****************************************************

AIPS ( Artificial Intelligent Partner System ) Homepage A009

hagiwara-yoshiaki@aiplab.com

*******************************************************

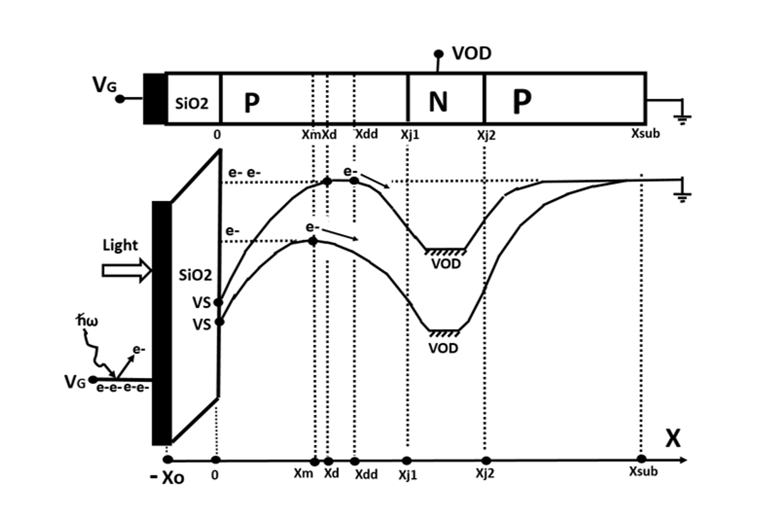

Device Physics of Pinned Photodiode

*******************************************************

*******************************************************

Device Physics of Pinned Photodiode

*******************************************************

:

Let's study slowly to understand these importart figures

related to the Pinned Photodiode. More explanations

will be given below.... take your time....

(1) Introduction

***************************************************

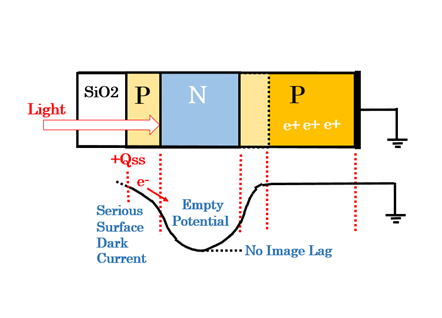

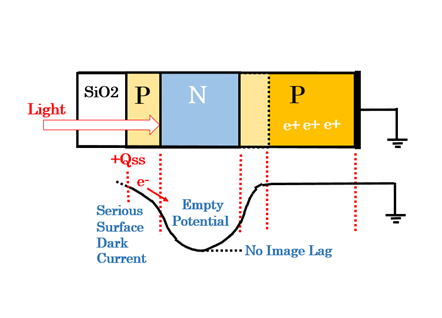

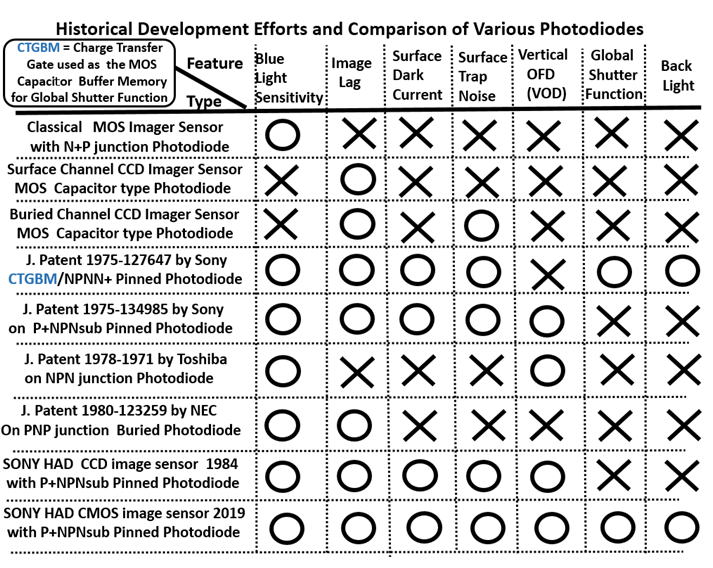

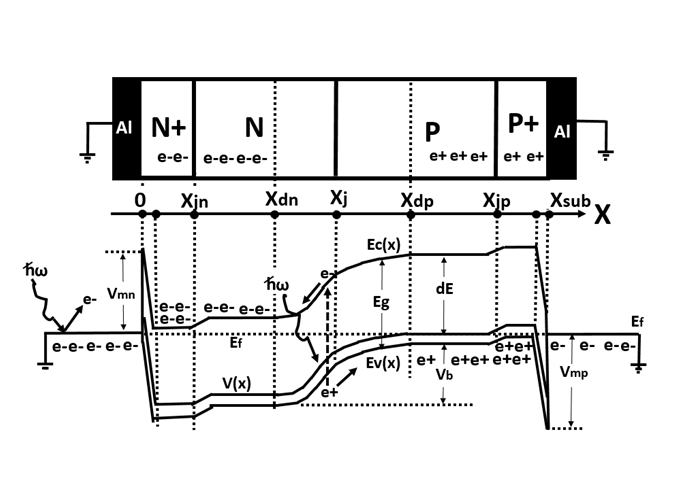

There are a variety of photodiodes in the development history

of solid state image sensors. The most important photodiode

among them is known as Pinned Photodiode which is a P+NP

junction type photodiode with the surface layer of highly doped

P+ hole accumulation region with the buried N region used for

collection and storage of the photo signal electron charge. The

Pinned Photodiode is actually identical to SONY Hole Accumulation

Diode (SONY HAD), the same photodiode structure but with two

different names. More over the difference of the Buired Photodiode

and the Pinned Photodiode is also not well understood. They are

now being used confusingly. However, precisely speaking, the

definition of the Pinned Photodiode has an important feature

difference from the definition of the Buried Photodiode.

Pinned Photodiode has by necessity the signal charge collectiong

buried N layer, therefore, Pinned Photodiode is by necessity the

Buried Photodiode. However, the Buried Photodiode is not by

nenessity a Pinned Photodiode that has many important features

as explained below.

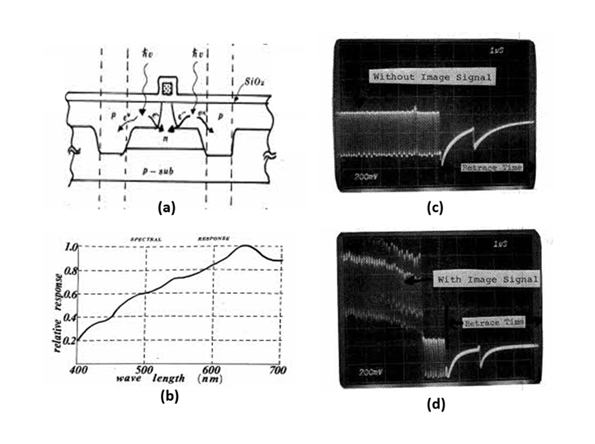

Moreover, the highly doped P+ layer of the surface hole

accumulation region in the Pinned Photodiode provides

the condition of zero surface electric field , creating a

higlhly light sensitive picture quality of a very low level

surface dark current noise.

The highly doped P+ layer, which also isolates and protects

the buried charge collecting N layer by quenching the

positively charged surface fixed charge Qss and the surface

carrier trapping interface states Nss, provides a very high

picuture quality of a vey low noise, free of 1/f trap noise.

Moreover, the signal charge, which is stored in the buied

N layer and protected by the highly P+ pinned surface

layer of surface hole accumulation, is to be transfered

to the adjacent charge transfer device (CTD) via the

charge transfer gate (CTG) by CCD like complete charge

transfer operation mode, creating a completely depleted

empty potential well in the buried N region.

Pinned Photodiode is now considered by necessity as

Depletion Photodiode which provides high quality

action pictures of low image lag. But this was not

always true in the early development of the photodiode

development efforts. See Japanese Patent 1975-127646.

The evidence that Hagiwara at SONY is the true inventor

of the Buired Photodiode will be shown in the application

example of the Japanese Patent 1975-127646 by Hagiwara

at SONY in 1975, and explained in details later below .

The Buried Photodiode is not, by necessity, the Depletion

Photodiode. The Buried Photodiode does not by necessity

have to have the signal charge to be transfered to the

adjacent charge transfer device (CTD) in the complete

charge transfer mode..

Detailes of the Depletion Photodiode is explained in

details later below.

The evidence that Hagiwara at SONY is the true inventor

of the Depletion Photodiode is also given in his Japanese

Patent 1975-127647 will be explained in details later below.

However, the Depletion Photodiode is not by necessity the

Pinned Photodiode. The Depletion Photodiode does not, by

necessity, have to have the highly doped P+ surface layer

of the hole accumulation region that provides a higlhly light

sensitive picture quality of very low surface dark current

and no 1/f trap noise.

Detailes of the Pinned Photodiode is explained in

details later below.

The evidence that Hagiwara at SONY in 1975 is the true

inventor of the Pinned Photodiode is also given in the

Japanese Patent 1975-134985 and in the Pinned Photodiode

1978 paper by Hagiwara on the P+NP junction type Pinned

Photodiode with the Pinned Window and the Pinned surface

potentail used in the 380H x 490V Frame Tranfer CCD type

charge transfer device (CTD). .

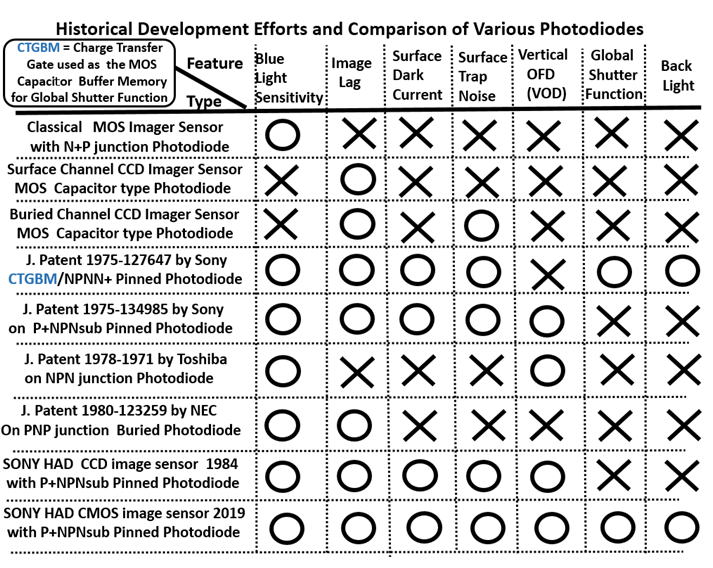

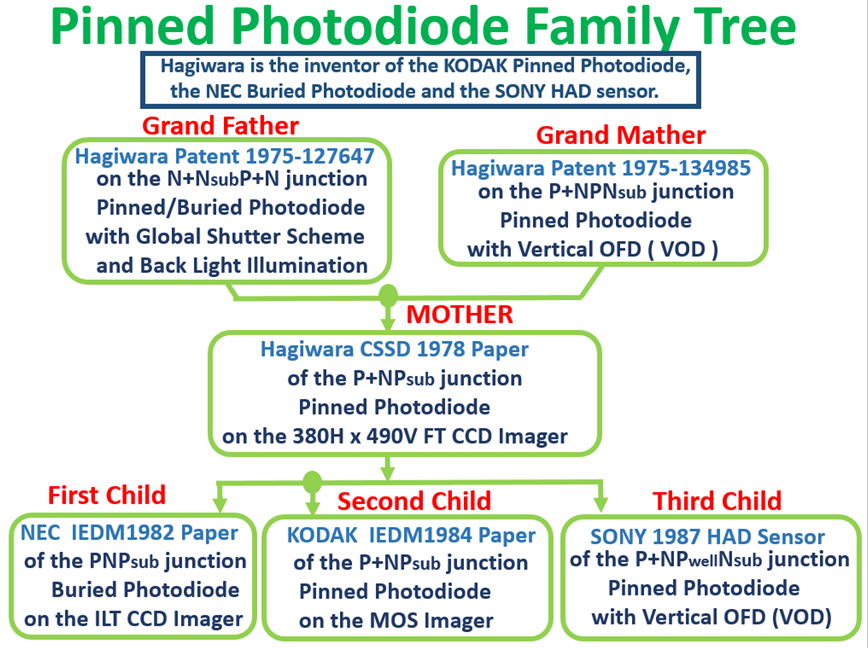

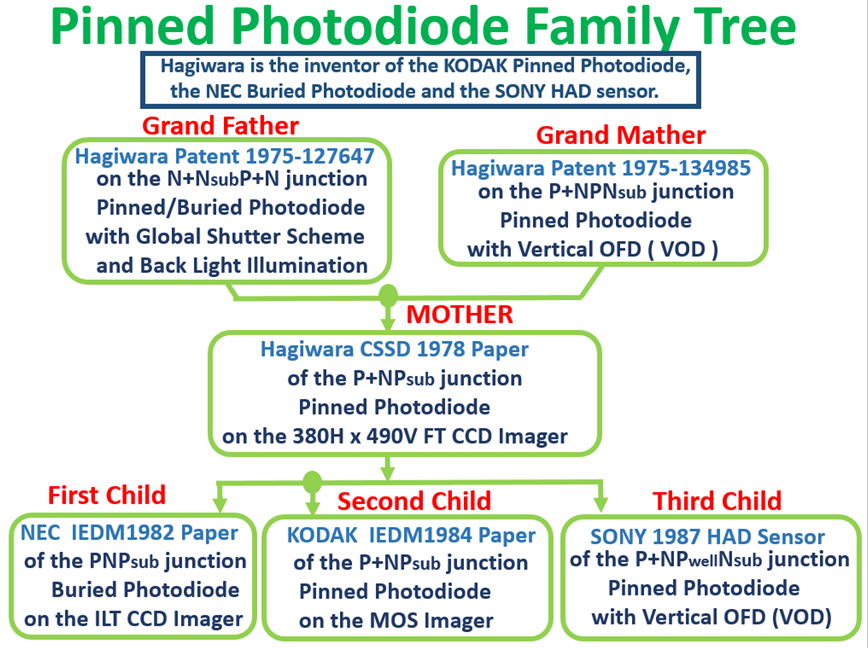

(2) Histoirical Events of Pinned Photodiode Development Efforts

*******************************************************

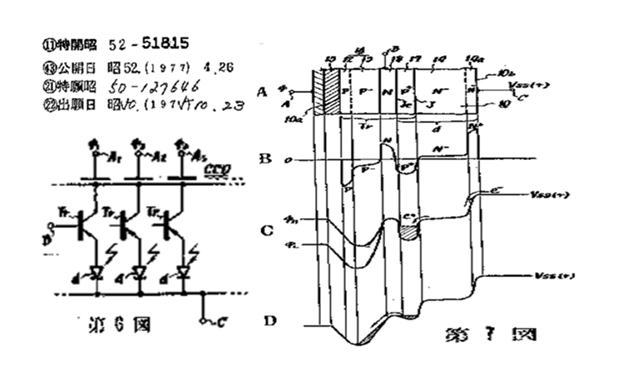

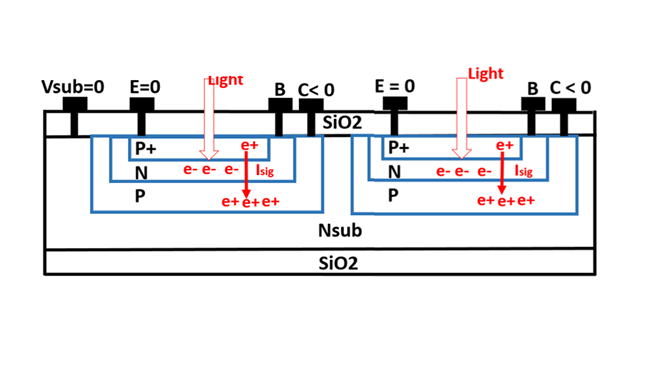

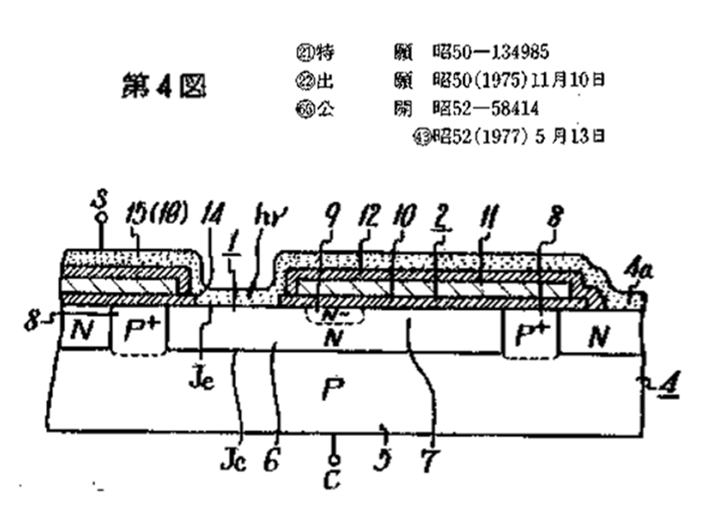

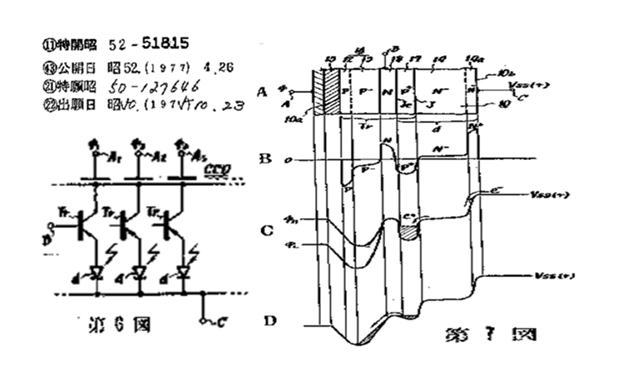

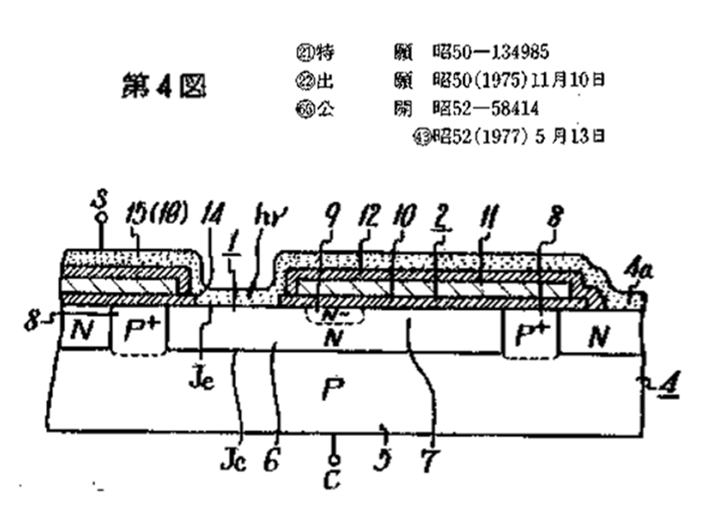

The first Buried Photodiode is proposed by Hagiwara at Sony

in 1975 in his Japanese Patent 1975-127646 in the form of

the N+N-P+NP-P junction type Buried Photodiode with the

relatively heavily doped buied charge collecting P+ layer.

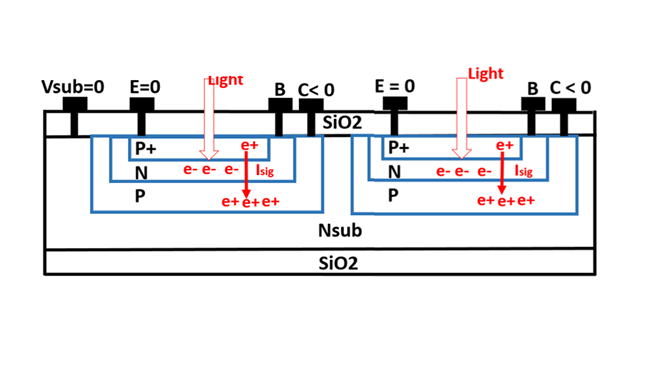

See Figure 19 below, which shows the Buried Photodiode with the

P+NP junction type bipolar transistor used fas the signal charge

transfer gating (CTG). The signal charge is to be transfered to the

surface MOS capacitor which acts as a temporary buffer storage

memory for global shutter operation scheme. The application

example drawn in the Japanese Patent 1975-127646 shows a case

of back illumination scheme.

It is well known that the visible light has the wave length of 0.4 um

to 0.6 um. The blue light of the 0.4 um wave length can penetrate

only about the 0.3um depth into the silicon crystal while the red

light of the 0.6 um wave length can penetrate into the silicon crystal

upto about at the 10 um depth. Hence to cover the whole range of

the visible light, the N+N-P+ N junction type Buried Photodiode

structure was essential. That is why the N- region was drawn

relatively wide in the application example shown in the Japanese

Patent 1975-127646 . The back side has the N+N impurity doping

profile which provides the barrie for the photo signal charge (e+)

to be directed to the P+ signal charge collecting buried P+ layer.

If the silicon wafer has more than 12 um thickness, the visible

light cannot reach the front surface of the surface MOS capacitor

which can be used as the temporary buffer memory for the

global shutter operation. We do not any extra blind formation

to protect the signal stored temporarily in the surface MOS

buffer memory capacitor.

Figure 21 shows the N+NP+ junction type Buried Photodiode,

drawn in the Japanese Patent 1975-127646 ( Oct 23, 1975 )

by Hagiwara at Sony , with the P+NP-P bipolar transistor type

Charge Transfer Gating (CTG) and with P-type Buried Channel

MOS Capacitor used as the temporary storage buffer memory

for Global Shutter operation in back light illumination scheme.

The Japanese Patent 1975-127646 ( Oct 23, 1975 ) by Hagiwara

at Sony is the evidence that Hagiwara at Sony is the true inventor

of the Buired Photodiode.

Figure 19

The N+NP+ junction type Buried Photodiode, drawn in the Japanese

Patent 1975-127646 ( Oct 23, 1975 ) by Hagiwara at Sony , with the

P+NP-P bipolar transistor type Charge Transfer Gating (CTG) and

with P-type Buried Channel MOS Capacitor used as the temporary

storage buffer memory for Global Shutter operation in back light

illumination scheme.

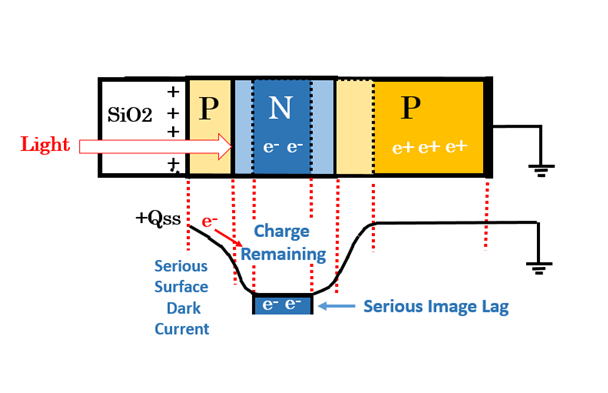

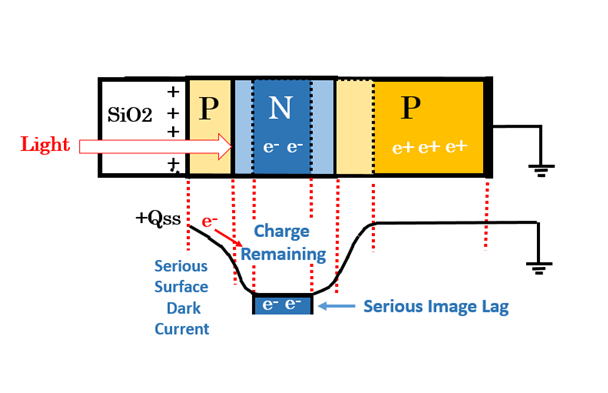

The Buried Photodiode (BPD) itself is a simple PNP junction type

photodiode that may still have the remaining signal charge (e+) in

the charge collection region when reset.

Buried Photodiode(BPD) is not by necessity Depletion Photodiode

(DPD) that has no image lag. Moreover, Buried Photodiode (BPD)

is not by necessity Pinned Photodiode (PPD) that has no dark

current.

The surface potential of the Buired Photodiode is not by necessity

pinned. Therefore, the surface electric field and the surface fixed

positive charge +Qss may generate the undesired serious dark

current that degrades image output quality and also creates silicon

chip yield problems.

However, as seen in the drawing of Japanese Patent 1975-127646,

this is a Pinned Photodiode with the Buried P+ charge collecting

and storage region. This is Buried Photodiode and also Pinned

Photodiode.

The Pinned Photodiode is by necessity Buried Photodiode.

This Japanese patent shows an example of the Pinned Photodiode,

which is by necessity Buried Photodiode.

The Pinned Photodiode is now considered normally by necessity

Depletion Photodiode. But this is not always true.

This Japanese patent shows an example of the Pinned Photodiode,

which is not, by necessity a Depletion Photodiode.

Anyway, this picture drawn in Hagiwara 1975 Japanese Patent

1975-127646 is the clear evidence that Hagiwara at SONY is

the true inventor of the Buried Photodiode in 1975.

The application example drwan by Hagiwara at Sony in 1975

in the Japanese Patent 1975-127646 was the P+ type charge

collecting buried layer with the hole signal charge (e+) .

However, the idea can be easily extended to the case of the

N type charge collecting buried layer with the negatively

charged electron signal charge (e-) as shown below.

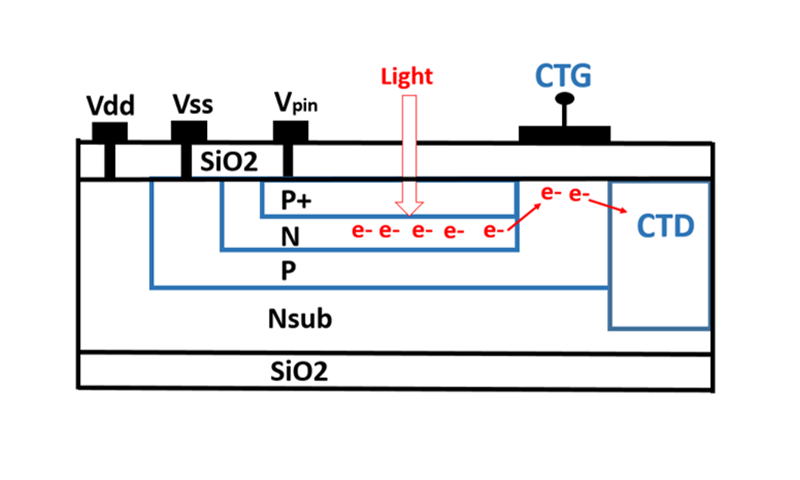

Figure 20

Hinted by the N+N-P+N junction type Buried Photodiode, with the

charge collecting and storage buried P+ layer, which is drawn in the

Japanese Patent 1975-127646 ( Oct 23, 1975 ) by Hagiwara at Sony,

the idea can be easily extended to the PNP junction type Buried

Photodiode with the N type charge collecting buried layer with the

negatively charged electron signal charge carrier (e-).

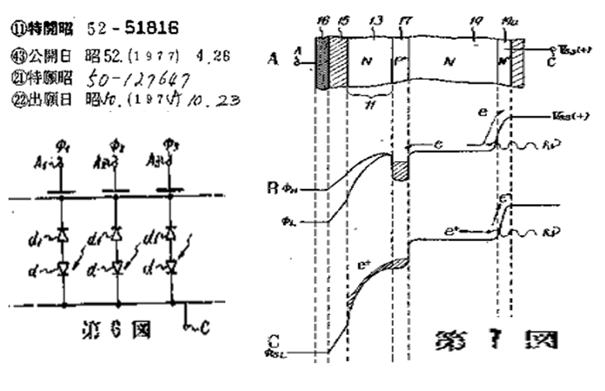

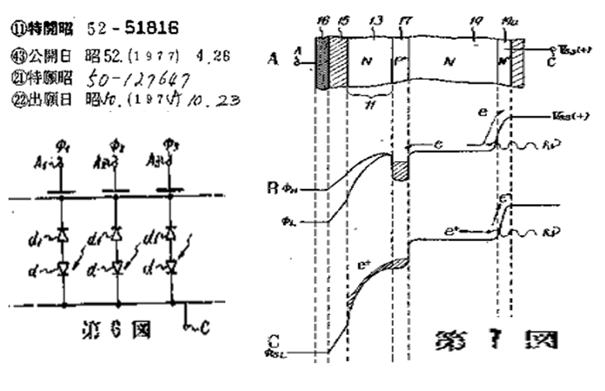

Moreover, hinted with this idea described in the Japanese Patent

1975-127646, described above, Hagiwara at SONY in 1975 also

filed at the same time another Japanese Patent 1975-127647 as

shown below in Figure 21.

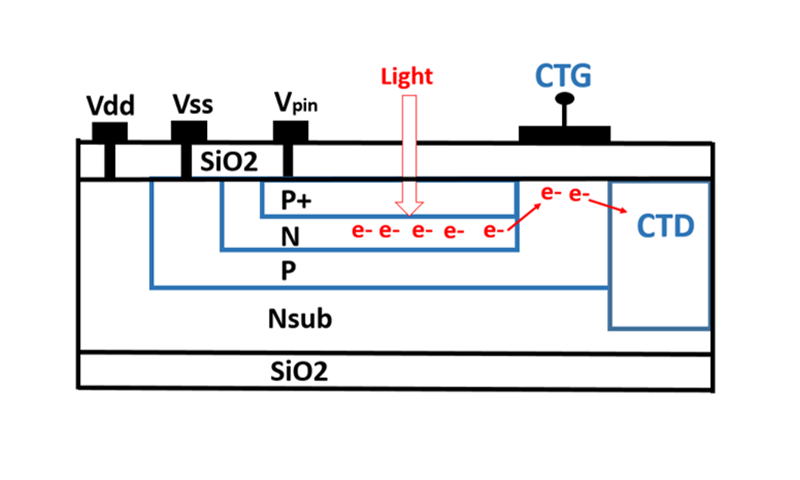

The N+NP+ junction type Depletion Photodiode, drawn in the Japanese

Patent 1975-127647 ( Oct 23, 1975 ) by Hagiwara at Sony, with P-type

Surface Channel MOS Capacitor used as the temporary storage buffer

memory for Global Shutter operation in back light illumination scheme.

This Depletion Photodiode is also a Buried Photodiode that has a charge

collecting and storage buried P+ layer. The signal charge is completely

depleted from the N buried storage region and transfered to the adjacent

MOS bufffer memory capacitor, providing a high picture quality of the

high speed fast action picture with no image lag picture.

The Japanese Patent 1975-127647 ( Oct 23, 1975 ) by Hagiwara

at Sony is the evidence that Hagiwara at Sony is the inventor of

the Depletion Photodiode with no image lag feature by the

complete charge transfer operation mode with the completely

emplty potential well.

Figure 21

The N+NP+ junction type Depletion Photodiode, drawn in the Japanese

Patent 1975-127647 ( Oct 23, 1975 ) by Hagiwara at Sony, with P-type

Surface Channel MOS Capacitor used as the temporary storage buffer

memory for Global Shutter operation in back light illumination scheme.

Figure 22

Hinted by the N+N-P+N junction type Depletion Photodiode, with the

charge collecting and storage buried P+ layer, which is drawn in the

Japanese Patent 1975-127647( Oct 23, 1975 ) by Hagiwara at Sony,

the idea can be easily extended to the PNP junction type Depletion

Photodiode with the N type charge collecting buried layer with the

negatively charged electron signal charge carrier (e-).

Pinned Photodiode has by necessity the signal charge collectiong

buried N layer, therefore, Pinned Photodiode is by necessity the

Buried Photodiode with the completely depleted of the signal

charge with the empty potential well when reset. The Pinned

Photodiode is now generally refered to have the Depletion

Photodiode feature of low image lag. Hence in general the

Pinned Photodiode is considered by necessity the Depletion

Photodiode. However, the Depletion Photodiode is not by

nenessity a Pinned Photodiode that has many important

features as explained below.

The highly doped P+ layer of the surface hole accumulation

region in the Pinned Photodiode provides the condition of

zero surface electric field , creating a higlhly light sensitive

picture quality of a very low level surface dark current noise.

The highly doped P+ layer, which also isolates and protects

the buried charge collecting N layer by quenching the

positively charged surface fixed charge Qss and the surface

carrier trapping interface states Nss, provides a very high

picuture quality of a vey low noise, free of 1/f trap noise.

The evidence that Hagiwara at SONY in 1975 is the true

inventor of the Pinned Photodiode is also given in the

Japanese Patent 1975-134985 and in the Pinned Photodiode

1978 paper by Hagiwara on the P+NP junction type Pinned

Photodiode with the Pinned Window and the Pinned surface

potentail used in the 380H x 490V Frame Tranfer CCD type

charge transfer device (CTD).

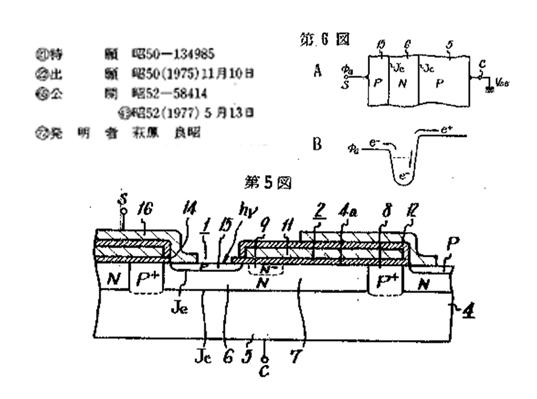

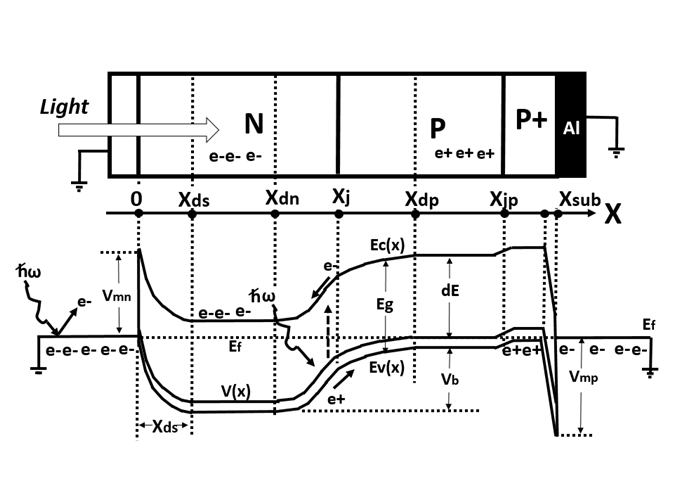

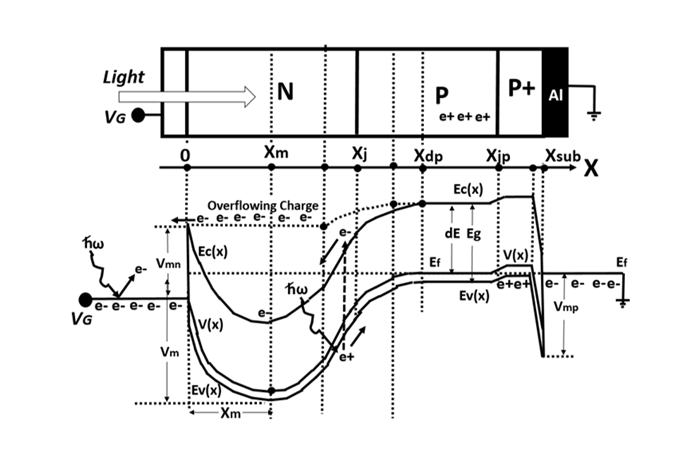

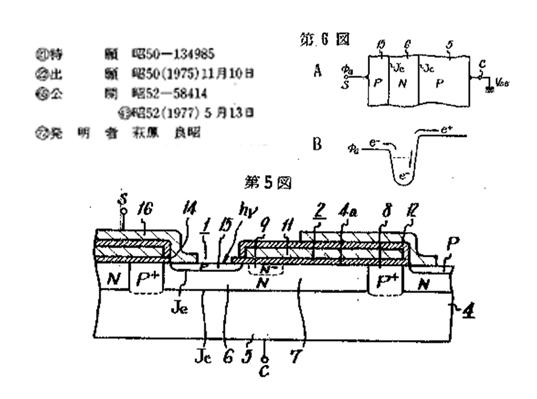

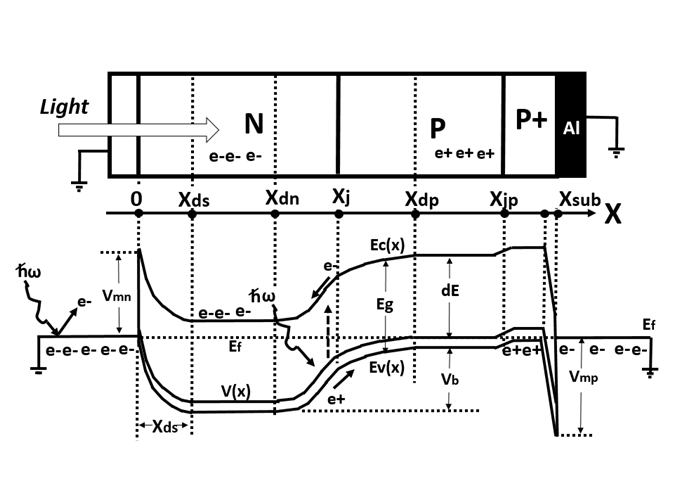

Figure 23

The Pinned photodiode with the heavily doped P+ surface layer,

drawn in the amplication example of the Hagiwara 1975 Japanese

Patent 1975-134985, which is used for the Buried Channel Interline

Transfer CCD image sensor.

The buried N type base region in the PNP junction type photodiode

structure has the same doping level of the lightly doped buried

channel CCD, and can be completely depleted of the signal charge

to the adjacent buried channel CCD type readout charge transfer

device (CTD) by the complete charge transfer so that we have

no image lag picture. It is cleat from the application exmaple

shown in the Japanese Patent 1975-134985 that this is also

the Depletion Photodiode.

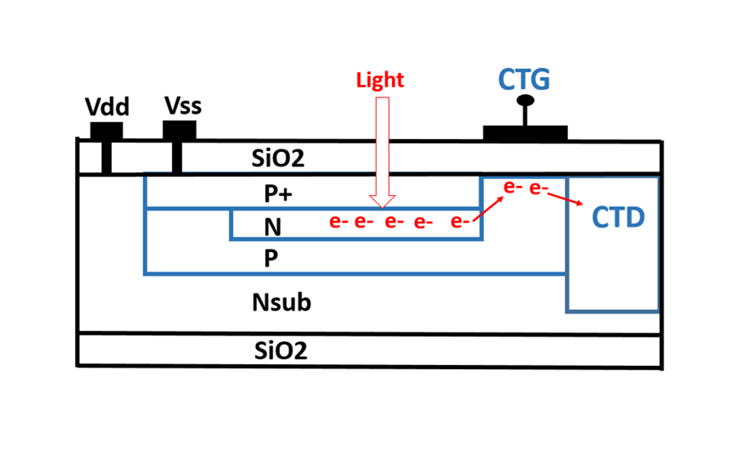

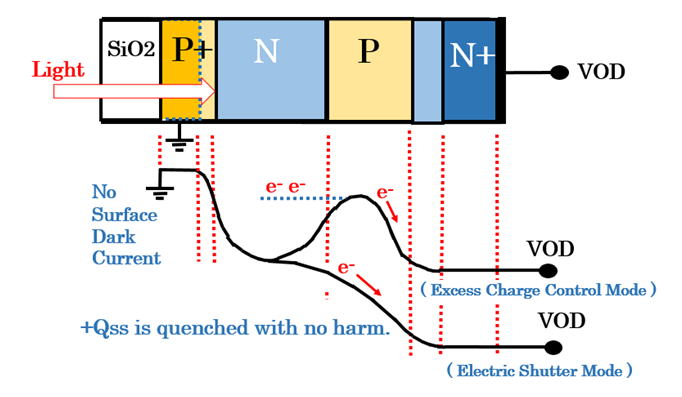

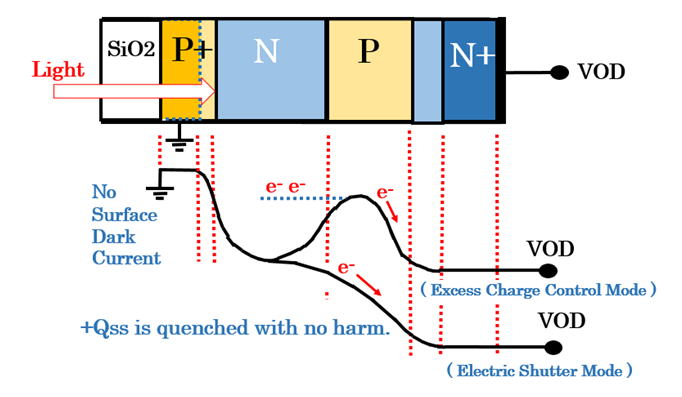

As shown in Figure 24 of the simplified P+NP junction type

Pinned Photodiode, the surface hole accumulation layer is

shown to have such a very heavily doped P+ region that can

have a fixed or Pinned potential by the external metal Ohmic

contact. The charge collecting N region is a buried N layer

under the P+ surface layer. Hence, this is also a Buried

Photodiode.Hence we conclude this is the Pinned Photodiode,

and also is Depletion Photodiode, and also is Bried Photodiode.

Hence the Pinned Photodiode is also by necessity Depletion

Photodiode with complete charge transfer operation mode.

Figure 24

The simplified P+NP junction type Pinned Photodiode structure

drawnin the Japanese Patent 1975-134985, whichi is also Depletion

Photodiode, and also is Buried Photodiode.

.

The evidence that Hagiwara at SONY in 1975 is the true

inventor of the Pinned Photodiode is also given in the

Japanese Patent 1975-134985 and in the Pinned Photodiode

1978 paper by Hagiwara on the P+NP junction type Pinned

Photodiode with the Pinned Window and the Pinned surface

potentail used in the 380H x 490V Frame Tranfer CCD type

charge transfer device (CTD). .

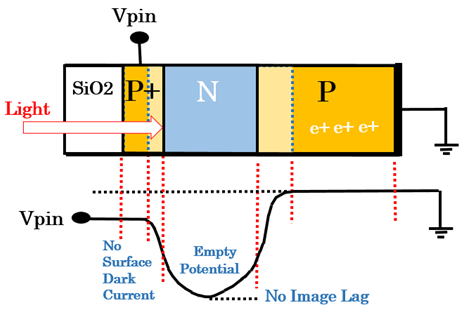

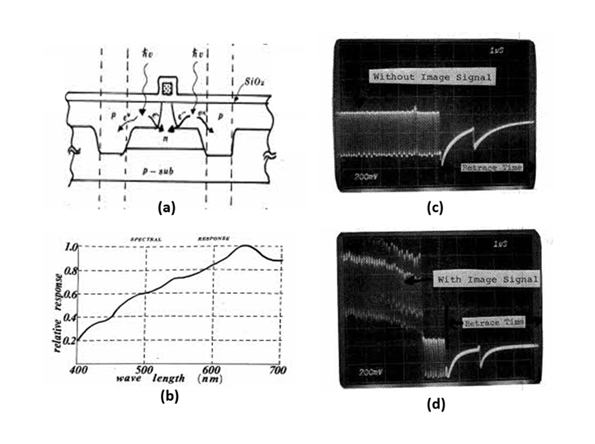

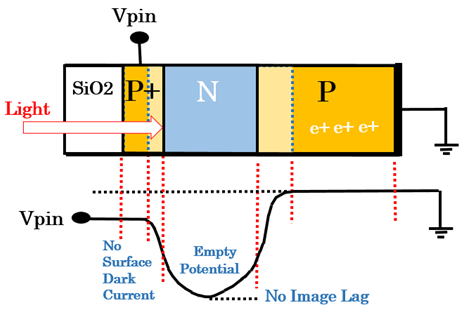

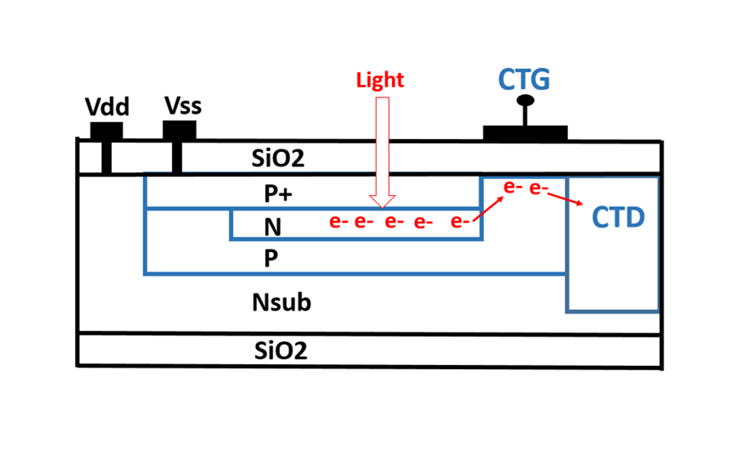

As shown in Figure 025 below, the image sensor has Pinned window

(a) with the heavily doped P+ Pinned Surface potential connected

to the substrate voltage by option with excellent blue light sensitivity.

(b). The P+NP junction type Pinned Photodiode with the self-aligned

boron atom ion implantation, forming the P+ hole accumulation

layer at the silicon surface to quench the surface dark current

as shown in the signal output wave form with no illuminated

light (c) and with illuminated light(d) .

See the Pinned Photodiode 1978 paper by Hagiwara

by Y. Daimon-Hagiwara, M. Abe, and C. Okada,

“A 380Hx488V CCD imager with narrow channel transfer

gates,” Proceedings of the 10th Conference on Solid State

Devices, Tokyo, 1978; Japanese Journalof Applied Physics ,

vol. 18, supplement 18-1, pp. 335-340, 1979.

Figure 25

The original Pinned window (a) with the heavily doped P+ Pinned

Surface potential connected to the substrate voltage by option

with excellent blue light sensitivity (b). The P+NP junction type

Pinned Photodiode with the self-aligned boron atom ion implantation,

forming the P+ hole accumulation layer at the silicon surface to

quench the surface dark current as shown in the signal output wave

form with no illuminated light (c) and with illuminated light(d) .

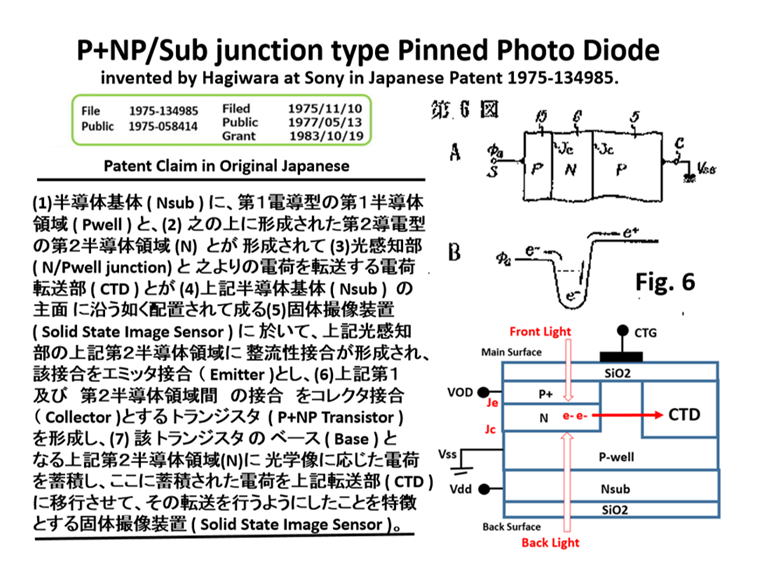

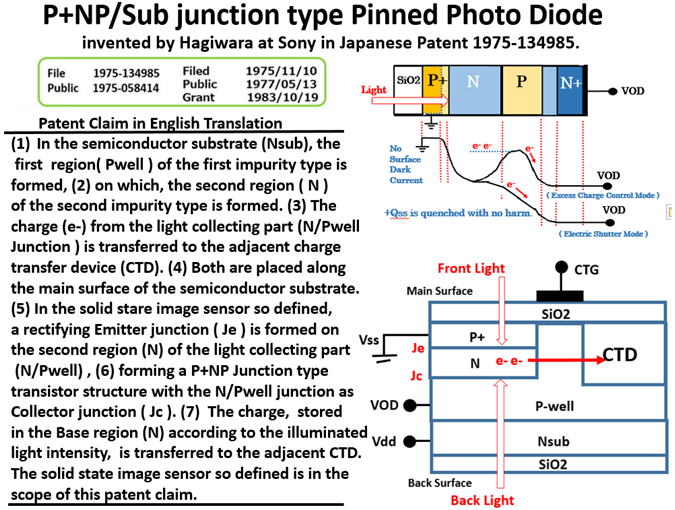

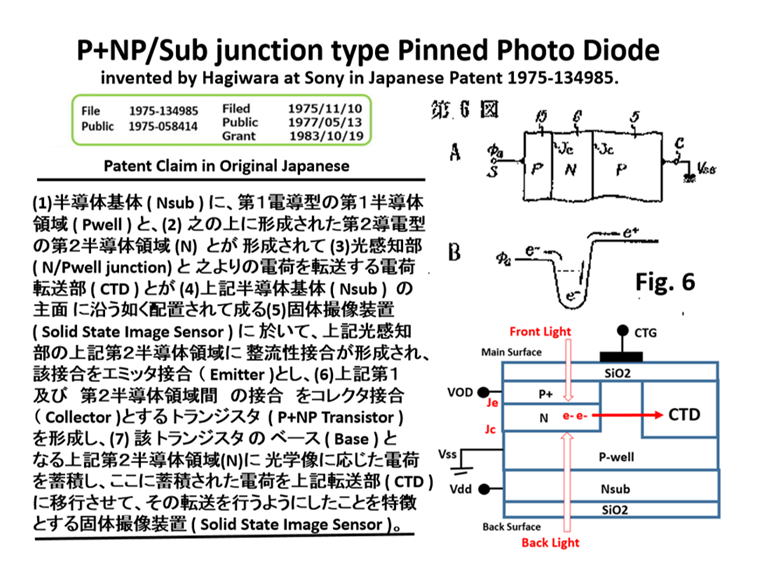

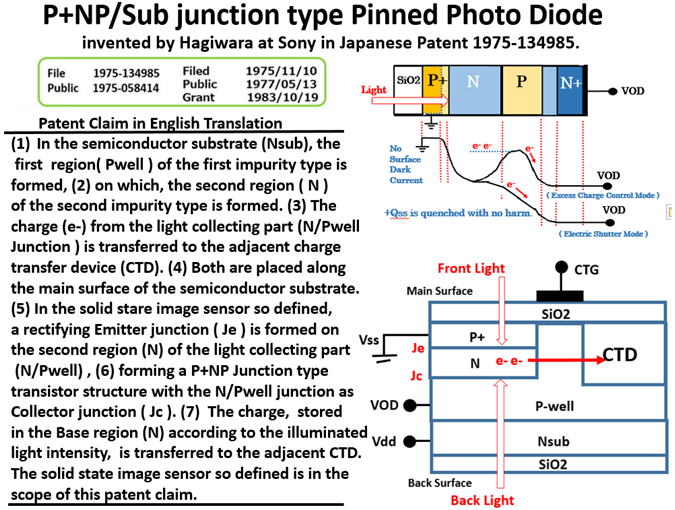

The patent claim of the Japanese Patent 1975-134985 actually

defined the P+NP junction bipolar transistor stucture in the

N type substrate.

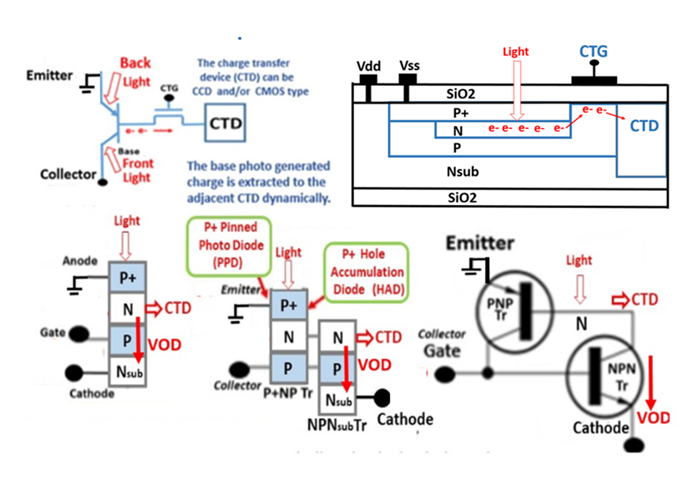

Figure 26a

Conventional Phototransistor in 1948. John Northrup Shive

(February 22, 1913 - June 1, 1984) is best known for inventing this

phototransistor in 1948 ( a device that combines the sensitivity to

light of a photodiode and the current gain of a transistor ). But he also

produced experimental evidence that holes could diffuse through

bulk germanium, and not just along the surface as previously thought.

This paved the way from Bardeen and Brattain's point-contact

transistor to Shockley's more-robust junction transistor.

Figure 26b

Dynamic Phototransistor with Floating Base used as Signal Charge Storage

Region, the original form of the P+NPNsub junction type Pinned Photodiode

invented by Hagiwara at Sony in 1975. See Japanese Patent 1975-134985.

Figure 26c

Dynamic Phototransistor with Floating Base used as Signal Charge

Storage Region, the P+NPNsub junction type Pinned Photodiode

with the Pinned Window with the Pinned surface potentail of

the P+ hole accumulation layer pinned directly by the substrate

voltage.

This is the SONY Hole Accumulation Diode (SONY HAD) invented

by Hagiwara at Sony in 1975 in Japanese Patent 1975-134985.

See also the paper “A 380Hx488V CCD imager with narrow channel

transfer gates,” by Y. Daimon-Hagiwara, M. Abe, and C. Okada,

Proceedings of the 10th Conference on Solid State Devices, Tokyo,

1978; Japanese Journal of Applied Physics , vol. 18, supplement 18-1,

pp. 335-340, 1979.

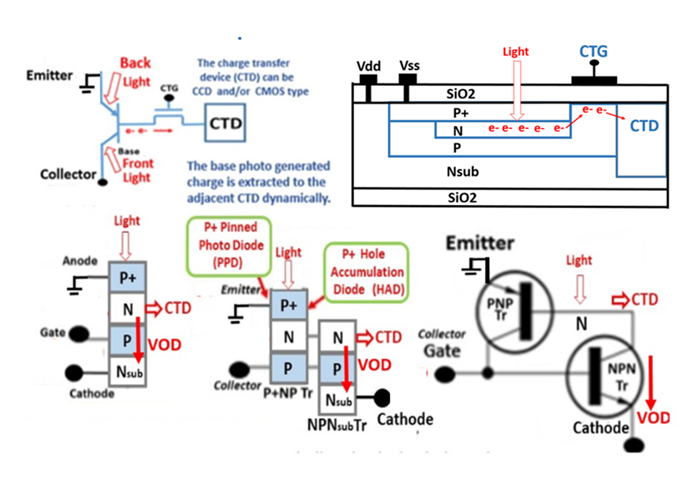

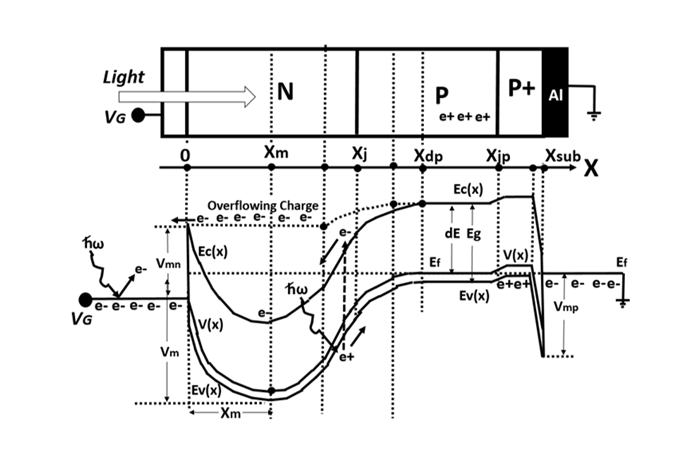

Figure 27

The P+NPNsub junction type Thyristor structure for the light collecting

device, invented by Hagiwara in Japanese Patent 1975-134985, which is

also the P+NP junction type Pinned Photodiode (PPD), Since this is

a P+NPNsub junction type Thyristor structure which has a variety of

device operation modes that includes the Thysistor punch thru action

mode that can be applied for the vertical overflow drain (VOD) function

controlling the overflowing signal charge at the high light beam.

Figure 28

The P+NPNsub junction type Pinned Photodiode (DPD), invented

by Hagiwara in Japanese Patent 1975-134985, is also by necessity

a Depletion Photodiode (DPD) and also by necessity a Buried

Photodiode(BPD). Since this is a P+NPNsub junction type Thyristor

structure which has a variety of device operation modes that includes

the Thysistor punch thru mode that can be applied for the vertical

overflow drain (VOD).

Figure 29

The patent claim of the original Japanese Patent 1975-134985 by

Hagiwara at Sony on the P+NPNsub junction type Pinned Photodiode.

Figure 30

The patent claim in English translation of the original Japanese

Patent 1975-134985 by Hagiwara at Sony on the P+NPNsub junction

type Pinned Photodiode.

Return to AIPS HOMEPAGE TOP

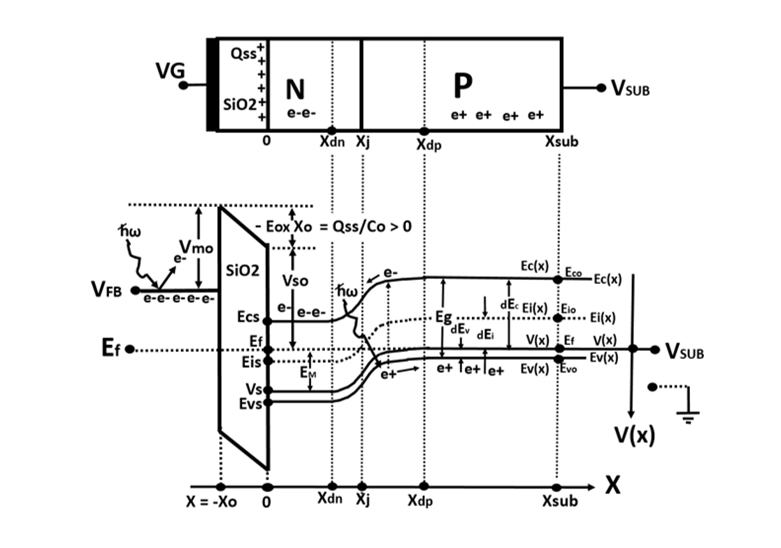

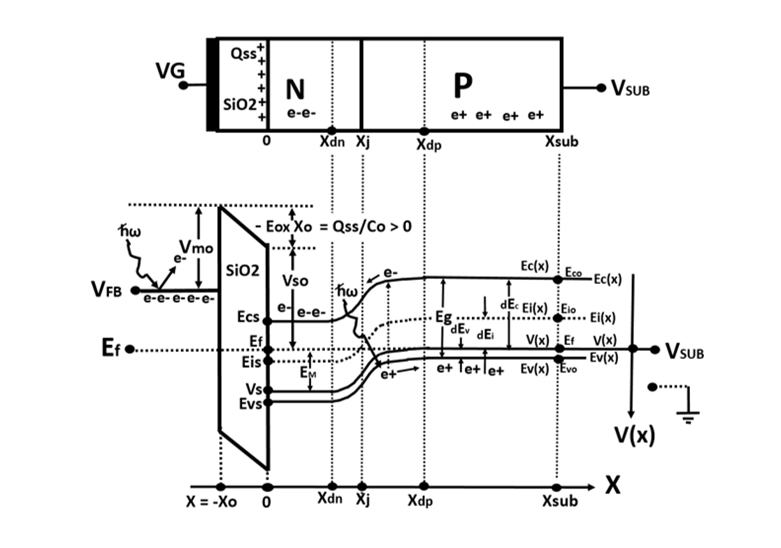

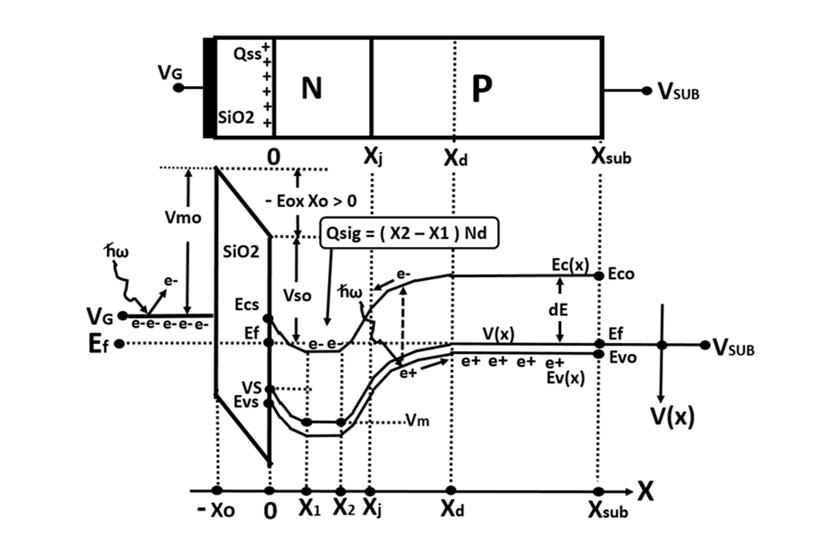

(1) Electrostatic Analysis of Surface Channel MOS Capacitor Structure

*************************************************************

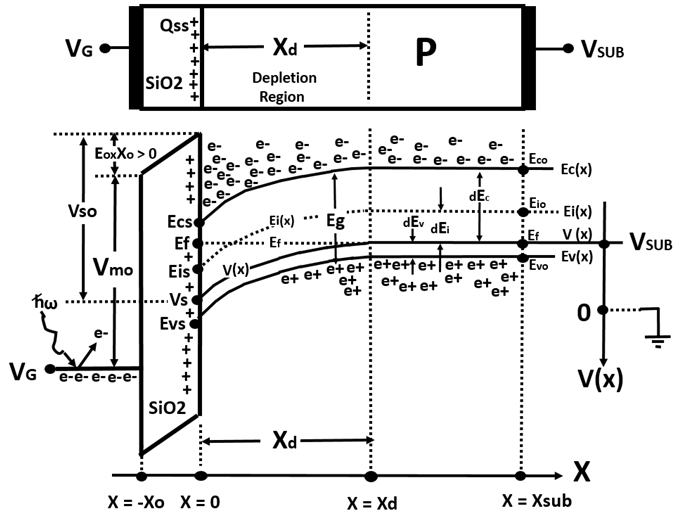

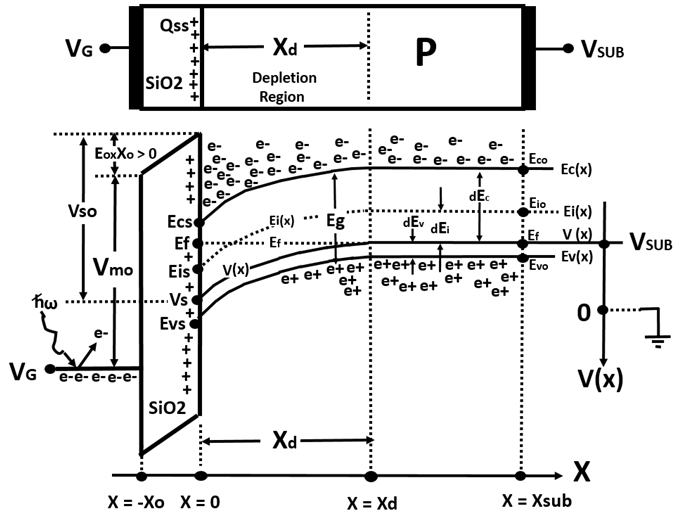

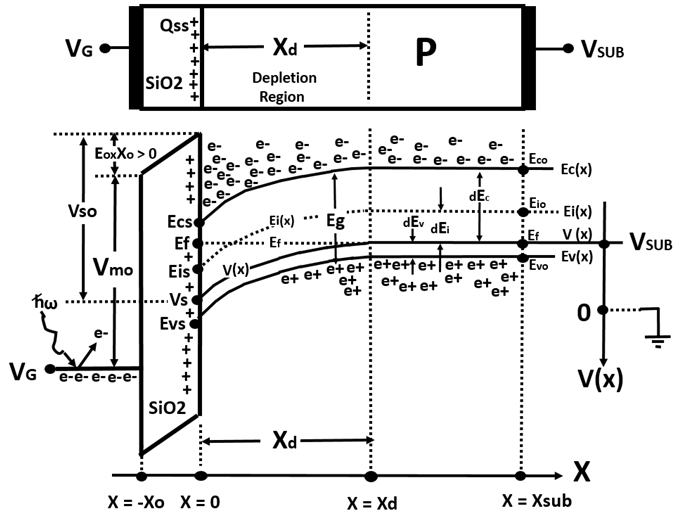

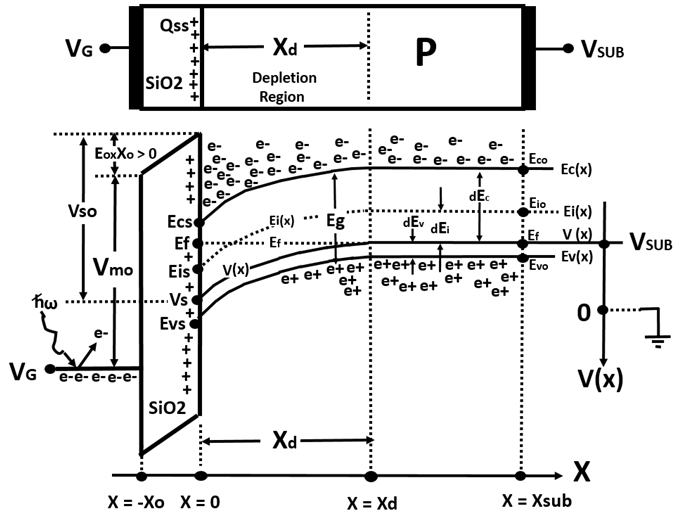

1.01 One Dimensional Metal/Oxide/Silicon (MOS) Structure

One dimensional metal/oxide/silicon (MOS) structure is illustrated in Fig.1.

Figure 1

The band diagram of one Dimension MOS structure of

P-type silicon wafer with a positive gate voltage

The structure consists of a metallic polysilicon gate followed by a layer of

silicon dioxide of thickness Xo which rests on the P type silicon substrate

with the impurity charge density Na.

Both sides of the metal oxide semiconductor (MOS) structure are pinned

by the external voltages. One side is pinned by the gate voltage VG which

has a strong influence on the values of the surface potential Vs, the surface

electric field Es and the depth of the depletion region Xd. The other side is

also pinned by the substrate bias voltage Vsub.

The value of the Fermi energy level Ef is defined to be the reference voltage

which is equal to the substrate bias voltage level Vsub. They provide the

boundary conditions for the Poisson equation that governs the internal

potential V(x), the density n(x) of the freely moving electron fog with

the negative electronic charge e- and the density p(x) of the freely floating

bubbles with the positive electronic charge e+ of hole carriers.

The Poisson equation for this one dimensional MOS structure, which is

governing the potential energy V(x) , the free charge carrier densities N(x)

for electrons and P(x) for holes, is shown below.

d*d V(x) / dx*dx = { D(x)+N(x) - P(x) } / Dsi …… (1)

The dielectric constants are denoted as Dsi in the silicon crystal and

Dox in the oxide. The impurity doping profile D(x) inside the silicon

wafer is given as a function the depth x in the silicon wafer.

We will solve this Poisson equation numerically for an arbitrary impurity

doping profile D(x). The metal oxide work function is denoted by Vmo

and the oxide semiconductor barrier height by Vso. The total offset

voltage drop ( VG - Vs ) across the gate oxide is given by

( VG - Vs ) = ( Vmo -Vso ) + EoxXo … (2)

We also have the following relationship by the Gauss law.

( Qss - Qsig )= Dsi Es - Dox Eox ……(3)

The positive fixed interface charge Qss is present at the silicon

surface at x = 0 and the amount of the effective total negative

mobile free electrons Qsig are attracted at the silicon surface x = 0

by the positive gate voltage VG. We denote the oxide capacitance

as Co = Dox/ Xo, and define the offset gate voltage VGG and

the semiconductor metal offset voltage Vsm.

VGG = VG + Vsm …(4a)

Vsm = ( Vso - Vmo ) + ( Qss - Qsig) / Co …(4b)

From these relationships we can obtain a relationship between

the surface potential Vs and the surface electric filed Es

at the silicon surface x = 0.

Vs + Dsi Es / Co = VGG … (5)

Rewriting Eq. (5), we also get the value of the surface electric field Es

as a function of the offset gate voltage VGG and the surface potential Vs.

Es = ( Co / Dsi ) ( VGG -Vs ) ………(6)

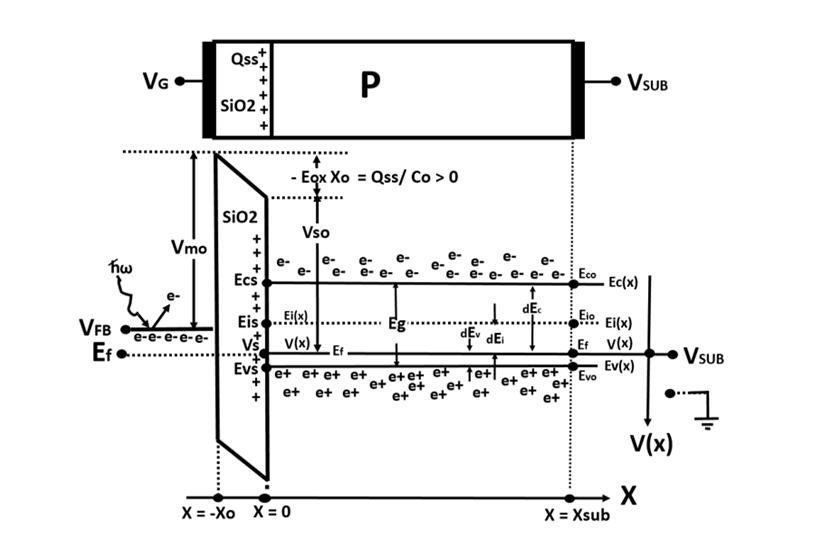

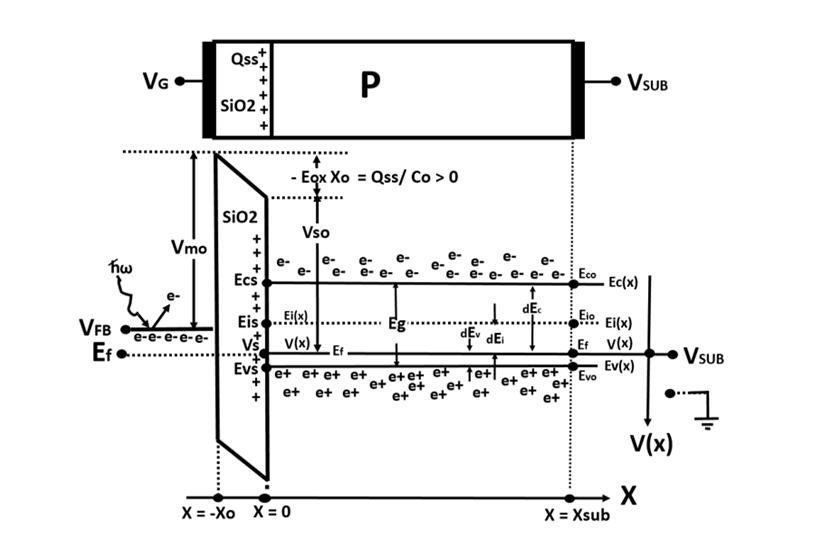

Figure 2

The band diagram of one Dimension MOS structure of

P-type silicon wafer at the flat band gate voltage.

As shown in Fig. 2, when we have a flat band condition, we have zero

surface electric field Es = 0. And at the flat band condition, the surface

potential Vs is equal to the substrate reference voltage Vsub which is

defined to be the level of the Fermi level. Hence we have Vs = Ef = Vsub.

Then, from the relationship given by Eq. (5) since we have Es =0, the

offset gate voltage VGG is equal to the surface potential Vs which is

equal to the reference Fermi energy level Ef.. That is, we have VGG = Ef.

Since the offset gate voltage VGG and the gate voltage VG are related

by Eq. (4a) and Eq. (4b), we obtain the flat band gate value VFB as shown

below.

VFB = Ef - Vsm ………(7)

When the gate voltage VG is equal to this flat band voltage VG = VFB ,

we have Es = 0 and Vs = Ef conversely. The presence of the positive fixed

charge Qss at the silicon oxide surface lowers the value of the flat band

voltage VFB as shown by Eq. (7) above with Eq. (4b).

When the gate voltage VG becomes greater than this flat band voltage VFB,

the minority carrier electrons will be attracted toward the silicon surface

and the silicon surface begins to form a channel for the mobile electrons

to flow. Historically, the understanding of the metal/Sio2 and Si/SiO2

barrier energies ( Vmo-Vso ) and the stabilizing the surface positive

fixed charge Qss played very important roles in the history of the early

PMOS and NMOS transistor integrated circuit fabrication processes.

1.02 Electron and Hole Mobile Charge Carriers at the thermal Equilibrium

At the thermal equilibrium, we have zero current density both for electron

and hole charge carriers. That is, we have Jn = 0 for electron charge carrier

density N(x) and Jp = 0 for hole charge carrier density P(x). Here we used

the Einstein relation ( μn / Dn ) = ( μp / Dp ) = ( kT/e ) .

Jn = - Dn dN(x)/dx +μn N(x) dV(x)/dx = 0 ……(8a)

Jp = - Dp dN(x)/dx -μp P(x) dV(x)/dx = 0 ……(8b)

The internal potential energy V(x) as a function of the silicon wafer

depth x is defined parallel to the band bending of the conduction energy

band edge Ec(x) , the valence band energy edge Ev(x) and the intrinsic

Fermi energy level Ei(x). And we have the following relationships with three

offset constant physical parameters, dEc, dEc and dEi defined in the

expressions shown below.

Ec (x) = V(x) - dEc = V(x) - (kT/e) ln ( Nc/No ) ……(9a)

Ev (x) = V(x) + dEv = V(x) + (kT/e) ln ( Nv/Po ) ……(9b)

Ei (x) = V(x) -dEi = V(x) - (kT/e) ln ( Ni/No ) ……(9c)

We can then express the electron and hole carrier densities N(x)

and P(x) in various ways as shown below.

N(x) = NC exp { ( Ec(x) -Ef ) / (kT/e) } ……(10a)

N(x) = Ni exp { ( Ei(x) - Ef ) / (kT/e) } ……(10b)

N(x) = No exp { ( V(x) - Ef ) / (kT/e) } ……(10c)

P(x) = NV exp { ( Ef - Ev(x) ) / (kT/e) } ……(11a)

P(x) = Ni exp { ( Ef - Ei(x) ) / (kT/e) } ……(11b)

P(x) = Po exp { ( Ef - V(x) ) / (kT/e) } ……(11c)

From these equations shown above, after some manipulations,

we get the basic relationships.

NoPo = Ni2 = NvNc exp {-Eg / (kT/e) } ……(12)

Ei(x) = (1/2) { Ec(x) + Ev(x) + (kT/e) ln ( Nc/Nv) } ………(13)

From the charge neutrality condition deep in the bulk

at the thermal equilibrium, we have

Po = Na + No. …… (14)

we obtain the values of the carrier densities No and Po

in the bulk at the thermal equilibrium in terms of the

uniform doping level Na and the intrinsic carrier density Ni.

Po = (1/2) { Na + sqrt ( Na2 + 4 Ni2 ) } ……(15a)

No = 2 Ni2 / { Na + sqrt ( Na2 + 4 Ni2 ) } ……(15b)

Figure 1

The band diagram of one Dimension MOS structure of

P-type silicon wafer with a positive gate voltage

As illustrated in Fig. 1, the values of the conduction band

energy edge Ec(x), the intrinsic Fermi level Ei(x) and the

conduction band edge Ev(x) at the silicon surface x = 0 are

denoted here respectively as Ecs = Ec(0), Eis = Ei(0) and

Evs = Ev(x) while at the silicon bulk deep in the substrate

at x = Xsub they are denoted as Eco = Ec ( Xsub ),

Eio = Ei ( Xsub ) and Evo = Ev ( Xsub ) respectively.

The surface potential at x =0 is denoted as Vs = V(0).

In the bulk, we have V(x) = Ef. Since in the bulk we have P(x)=Po

and N(x)=No. We also have the following relationships in the bulk.

No = NC exp { ( Eco-Ef ) / (kT/e) } ……(16a)

No = Ni exp { ( Eio - Ef ) / (kT/e) } ……(16b)

Po = NV exp { ( Ef - Evo ) / (kT/e) } ……(16c)

Po = Ni exp { ( Ef -Eio ) / (kT/e) } ……(16d)

( Eco - Ef ) = (kT/e) ln ( No /NC ) ……(17a)

( Eio - Ef ) = (kT/e) ln ( No /Ni ) ……(17b)

( Ef - Evo ) = (kT/e) ln ( Po /NV) ……(17c)

( Ef - Eio ) = (kT/e) ln ( Po /Ni) ……(17d)

As we increase the substrate impurity concentration Na, the hole

carrier density Po in the bulk in the thermal equilibrium also

increases. Normally the ratio Nv / Po is greater than 1 but

approaches to 1 as the value of Na, and hence Po also, gets

closer to the value of the effective carrier density Nv.

In the degenerate semiconductor, the ratio Nv/Po approaches

to 1. Therefore as we increase the wafer doping level Na

furthermore, eventually we will have the degenerate P+ silicon

wafer with the valence band edge Evo in the bulk equal to

the Fermi level Ef . That is, we will have Evo = Ef in the bulk.

From the relationship Eq. (12) in this degenerate P+ silicon

wafer, with the condition Po = Nv and Evo = Ef , we conclude

dEc = Eg which gives Eco = Ef - Eg.

At the same time, we will also have that the internal voltage V(x)

gets very close to the valence band edge Ev(x). And for the

degenerate P+ semiconductor, we have V(x) = Ev(x) throughout

inside the silicon wafer

1.03 Strong Inversion Condition

The strong inversion condition is defined as N(0) = Po , that is,

when the minority electron density N(x) at the silicon surface x=0

is equal to the density Po of the majority carrier in the bulk

at the thermal equilibrium. The threshold voltage Vth is defined

to be the gate voltage VG which creates this strong inversion

condition, N(0) = Po.

At this condition, the silicon surface becomes conductive and

creates a channel for the electric current to flow. When this

MOS capacitor is used as the gate structure of a MOS transistor,

the threshold voltage Vth is also called as the turn on voltage

to create a channel under the MOS gate for the electron current

to flow.

The strong inversion condition is defined at N(0) = Po.

Hence we also have the following relationships at the strong

inversion condition.

Po = NC exp { ( Ecs -Ef ) / (kT/e) } ……(18a)

Po = Ni exp { ( Eis - Ef ) / (kT/e) } ……(18b)

Po = No exp { ( Vs - Ef ) / (kT/e) } ……(18c)

The threshold gate voltage Vth is defined to be the gate voltage

VG that turns on the strong inversion condition when the minority

carrier electron density N(x) at the silicon surface x= 0 becomes

the bulk majority carrier density Po.

That is, at this gate voltage VG = Vth, the surface electron carrier

density becomes equal to the substrate doping level N(0) = Po.

We obtain the total band bending ( Vs - Ef )

at the onset of the strong inversion from Eq. (18c) as

( Vs - Ef ) = (kT/e) ln( Po / No ) ……(19)

Here we define the physical parameter VB to be one half of

the total band bending ( Vs - Ef ) at the onset of the strong

inversion. From Eq. (12), we then have the following relationships.

2VB = ( Vs - Ef ) = (kT/e) ln( Po / No ) ……(20a)

VB = ( kT / e ) ln( Ni / No ) = ( kT / e ) ln( Po / Ni ) ……(20b)

Writing the intrinsic fermi level at the surface x = 0 as Eis = Ei(x),

at the turn on gate voltage VG =Vth with the condition N(x) = Po

at the surface x = 0, from Eq. (18b) we obtain

Eis = Ef + ( kT / e ) ln( Po / Ni ) ……(21a)

And in the bulk by writing Eio = Ei ( Xsub ) from Eq. (16b) we obtain

Eio = Ef -( kT/e ) ln ( Ni/No ) ……(21b)

Then, from Eq. (21a) and Eq. (21b) we have

VB = ( Ef - Eio ) = ( Eis - Ef ) ……(21c)

At this strong inversion turn on gate voltage Vth, with the internal

voltage V(x) axis defined downward for the negatively charge electron

carriers, the intrinsic Fermi level Eio at the bulk will be above the Fermi

level Ef by the amount ( Ef - Eio ) = VB > 0 as much as the intrinsic

Fermi level Eis at the silicon surface is below the intrinsic Fermi level Ef,

by the amount ( Eis - Ef ) = VB > 0.

1.04 Depletion Approximation

By depletion approximation, inside the depletion region, by assuming

n(x) = p(x) = 0 and D(x) = Na and the boundary conditions V(x) = Vs

at x =0 and V(x) = 0 at x = Xd, we can express the internal voltage V(x)

as a function of the position x shown below.

V(x) = Ef -( Na/2Dsi ) ( Xd - x )**2 ………(22a)

V(x) = Vs -Es x + ( Na/2Dsi ) x** 2 ………(22b)

And the electric field E(x)= - dV(x)/dx inside the depletion region

can be expressed as

E(x) = ( Na/Dsi ) ( Xd - x ) ………(23a)

E(x) = Es- ( Na/Dsi ) x ………(23b)

At the edge x = Xd, of the depletion region,

we have the conditions V(x) = Ef = Vsub

and E(x) = 0 while at the silicon surface x = 0,

we have V(x) = Vs and E(x) = Es.

Then we obtain the following relationships

between the total band bending (Vs-Ef)

and the surface electric field Es.

Vs - Ef = NaXd**2 / 2Dsi ……(24a)

Es = NaXd / Dsi ……(24b)

Vs - Ef = DsiEs**2/2Na ……(24c)

Using the relation given by Eq. (5) and Eq. (24b),

the depletion depth Xd can be expressed as a function

of the surface potential Vs and the offset gate voltage

VGG as shown below,.

Xd = ( Co / Na )( VGG - Vs ) … (25)

By introducing the physical parameters

VA = DsiNa/Co**2,

we can now obtain the value of the offset gate

voltage (VGG - Ef ) as a function of the surface

potential ( Vs -Ef ) from the relationship below.

( VGG - Vs ) = sqrt { 2 ( Vs - Ef ) VA } … (26)

At the onset of the turn on gate voltage VG=Vth, we have

( Vs - Ef ) = 2 VB … (27)

We then have at the onset of the turn on gate voltage VG=Vth,

( VGG - Ef ) = 2 VB + 2 sqrt ( VA VB ) … (28)

Then from the relationship Eq. (4a) we have

the value of the threshold voltage Vth.

Vth = Ef - Vmo+2 VB + 2 sqrt ( VA VB ) ….. (29)

Conversely, although the mathematical derivation

is not simple, we can also obtain the surface

potential ( Vs - Ef ) as a function of the offset

gate voltage (VGG - Ef ).

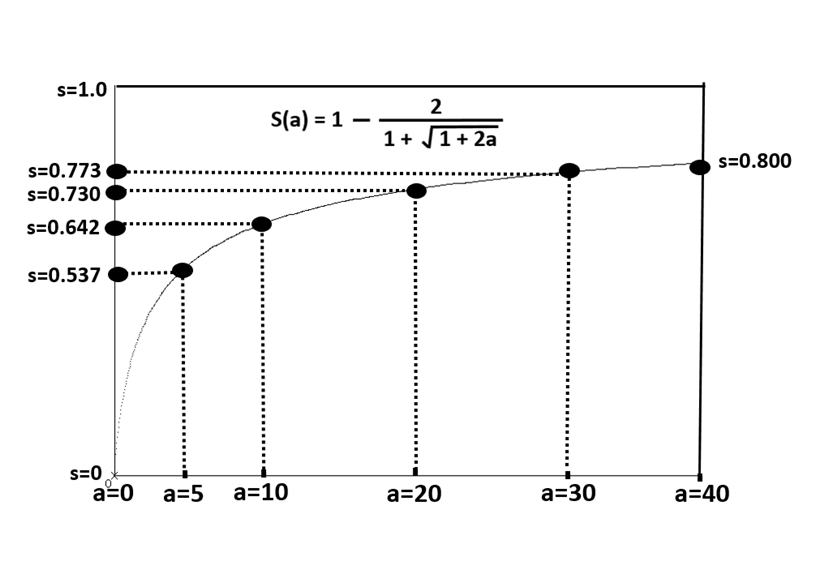

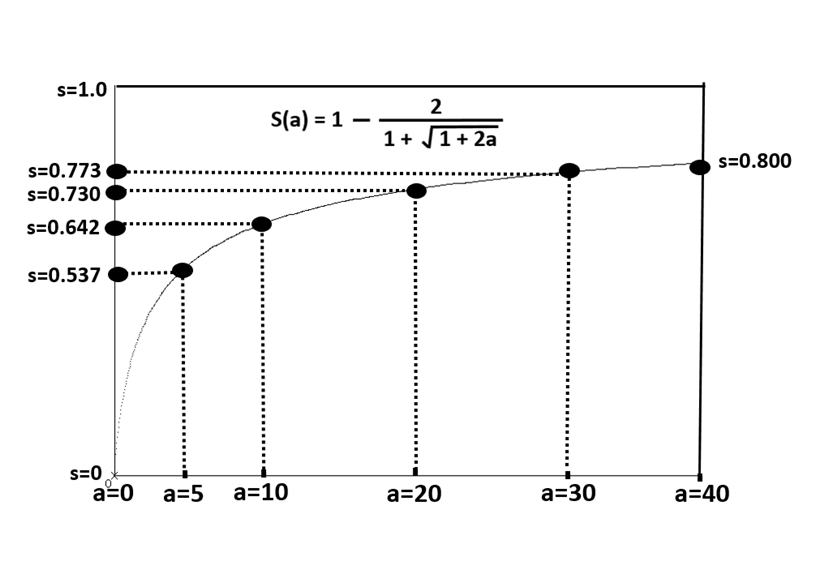

Figure 3

The values of the function S = S(a) plotted against

the input physical parameter a = VGG/VA.

We use the function S(a) shown in Fig. 3 and defined

by the following relationships with the parameter a.

a = ( VGG - Ef ) / VA … (30a)

S(a) = 1 -2 / { 1 + sqrt ( 1 + 2a) } … (30b)

( Vs -Ef ) = VA S(a) … (30c)

The value of the function S(a) increases monotonically as the input

variable a increases. However, the value S(a) is always less than 1,

but very slowly approaching to 1.

To obtain some feelings for these relationships, we now put some values

for the salient physical parameters involved in the MOS capacitor structure

under consideration.

Here we choose the substrate doping level Na=500 e /μm3 with the oxide

thickness Xo = 0.13 μm.

The dielectric constant of the silicon dioxide is Dox = 216 eV/μm

while the dielectric constant of the silicon crystal is Dox = 648 eV /μm.

We have then the oxide capacitance of Co = Dox/Xo = 1662 e/voltμm2.

The value of the parameter VA is given as VA = DsiNa/Co2 = 0.117361 V.

The effective conduction band electron density Nc = 2.8 x 107 e /μm3 and

the effective valence band hole density Nv = 1.04 x 107 e /μm3 are used

with the silicon energy gap of Eg = 1.082 V, to obtain the intrinsic carrier

concentration of Ni = 0.0145 e /μm3 by the relationship Eq. (12).

The value of the bulk majority carrier concentration Po obtained by Eq. (15a),

is greater than the impurity doping level Na=500 e /μm3 slightly but is very

close to Na.

We have the minority carrier electron density of No = 4.19 x 10-7 e /μm3 <<Na

in the deep bulk substrate at the thermal equilibrium from Eq. (15b).

Then, Eq. (20a) gives the total bending 2VB = 0.541316 V at the onset of the

strong inversion. We then obtain the depletion depth Xd = 1.184522 μm by Eq. (25).

And subsequently we obtain by Eq. (24b) the surface electric field of Es = 0.913983 V/μm.

Eq. (3) gives the oxide electric field Eox =2.741949 V/μm.

Using (Vso-Vmo ) = (4.45-3.20) = 1.15 eV (1) with the relationship Eq. (27)

at the onset of the strong inversion, we get ( Vth - Ef ) =- 0.252230 V from Eq. (29).

If we let the gate voltage ( VG - Ef ) = -0.252230 V,

we have VGG = 0.897770 V from Eq. (4a) conversely

with Vsm= (Vso - Vmo ) = (4.45 - 3.20) = 1.15 eV .

See Ref(1) below.

And then the value of a = VGG/VA = 7.649636 gives S(a) = 0.602957.

We get ( Vs-Ef ) = VGG S(a) = 0.541316 V by Eq. (30c) in return as before.

We get the total band bending of ( Vs - Ef ) =2 VB =0.541316 V.

We also confirm the value of VGG = 0.897770 V with the surface

potential ( Vs - Ef ) =0.541316 V and the surface electric field

of Es = 0.913983 V/μm from Eq. (5).

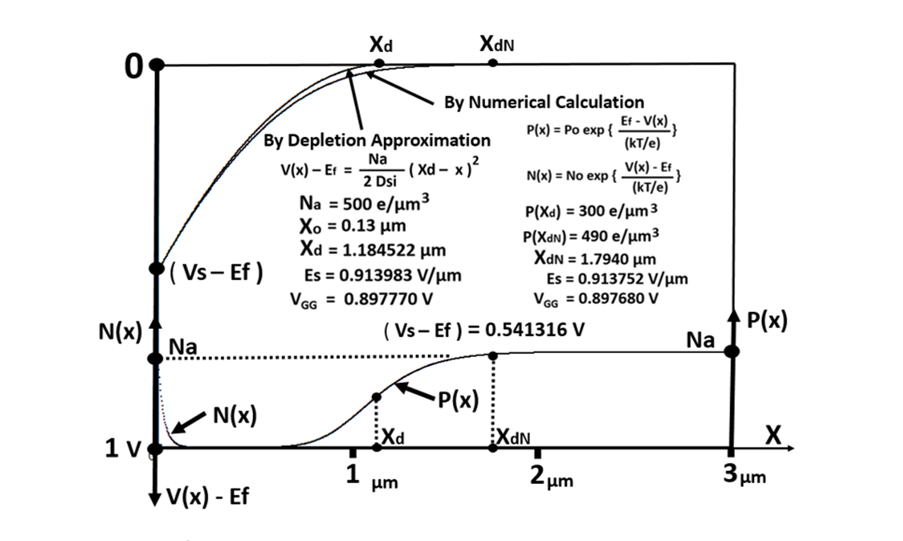

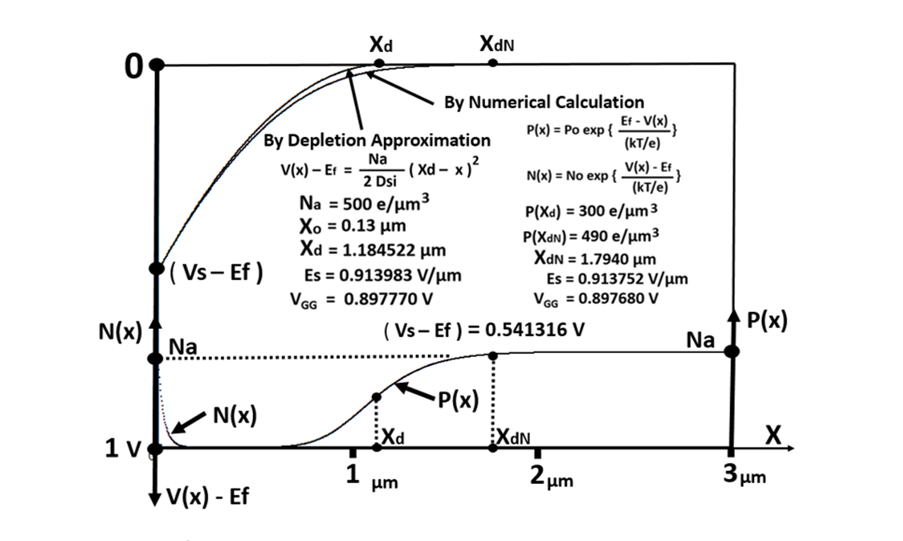

The potential curve V(x) as a function of the silicon depth x is plotted

in Fig. 4 by the depletion approximation is compared with the curve

obtained by the exact numerical computation.

Figure 4

The internal potential V(x) and the mobile electron and

hole densities P(x) and N(x) at the onset of the strong

inversion condition.

We observe that the majority carrier hole density P(x) is nonzero

and gradually increasing in the depletion region, and has the value

of P(Xd) = 300 e/μm3, at the depletion depth Xd = 1.1845 μm.

The electric field exits in the deep depletion region in both case.

However, the actual depletion depth calculated by the numerical calculation

is Xdn = 1.7940 μm which is much deeper than the depletion approximation

depth Xd.

The actual value Xdn = 1.7940 μm, is defined at the condition

of P(Xdn) = 490 e/μm3, where the majority carrier hole density P(x)

began to reach about 98% of the bulk majority carrier density of 500 e/μm3.

1.05 Surface and Bulk Dark Current Generation

The generation of the surface dark current will give a bad picture quality

if this MOS capacitor structure is used as a light detecting device.

The surface current generation rate Gsurface(x) and the bulk current

generation rate Gbulk(x) are respectively given below.

Gsurface (x) = ( So / 2Ni ) { Ni2 -P(x) N(x) } … (31a)

Gbulk (x) = { Ni2 - P(x) N(x) }/ ( 2 Niτ) … (31b)

Here So is the surface recombination velocity which has the value

of about So = 5 x 10**7 μm/sec. And the value of the bulk recombination

timeτis about τ= 10**-7 sec. At the silicon surface under the strong

electric field the carriers are completely depleted, and we have N(x) = P(x) = 0.

And with the value of the intrinsic carrier density Ni = 0.0145 e /μm3 we have

the surface generation rate of Gsurface = So Ni / 2 = 3.625 x 105 e / sec・μm2 .

With 1/60 sec integration time and the light detecting unit window area of 1μm2

we have the surface dark current of 6042 electrons, which is too large to be ignored.

We also obtain the bulk generation rate Gbulk = Ni / 2τ= 7.25 x 10**4 e / sec・μm3.

And the 1/60 sec integration time with the unit space volume of 1 μm3 of the

depletion region gives the bulk dark current of 1208 electrons which is less than

the surface dark current but still very large to be ignored.

As long as we use the MOS capacitor type light detecting device, we cannot

avoid the large surface dark current.

However, we can reduce the bulk dark current by reducing the effective

volume of the space depletion region if we form properly a heavily doped

buried P+ layer by deep high energy ion implantation as shown in the Fig.

5

below since we can reduce the volume of the space depletion region by

decreasing the depth Xd of the depletion region.

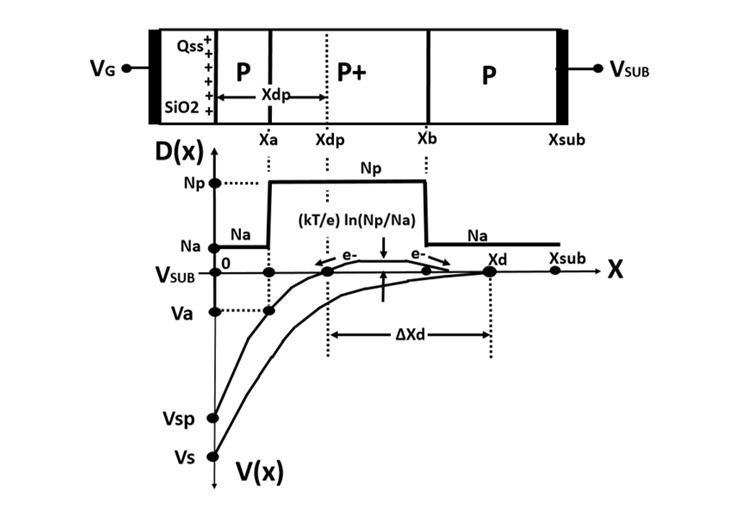

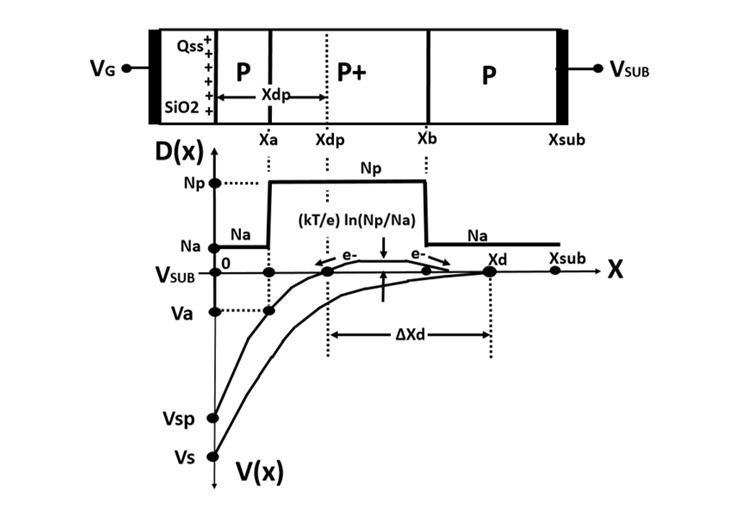

Figure 5

The impurity doping profile D(x) for the heavily doped

buried P+ layer and the internal potential V(x)

The heavily doped buried P+ layer can terminate the electric field in the

depletion region and the depth of the depletion region becomes shallower,

resulting a smaller volume of the depletion space region that gives a smaller

value for the bulk dark current.

Once the value of the surface potential Vs is known,

the depletion depth Xd for the uniform doping case

can be calculated and is given as Xd = ( Co / Na )( VGG - Vs ).

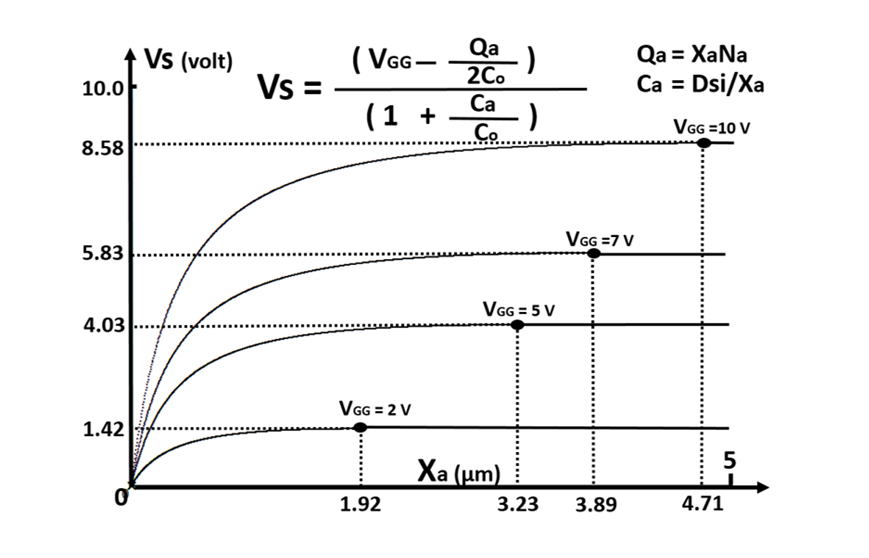

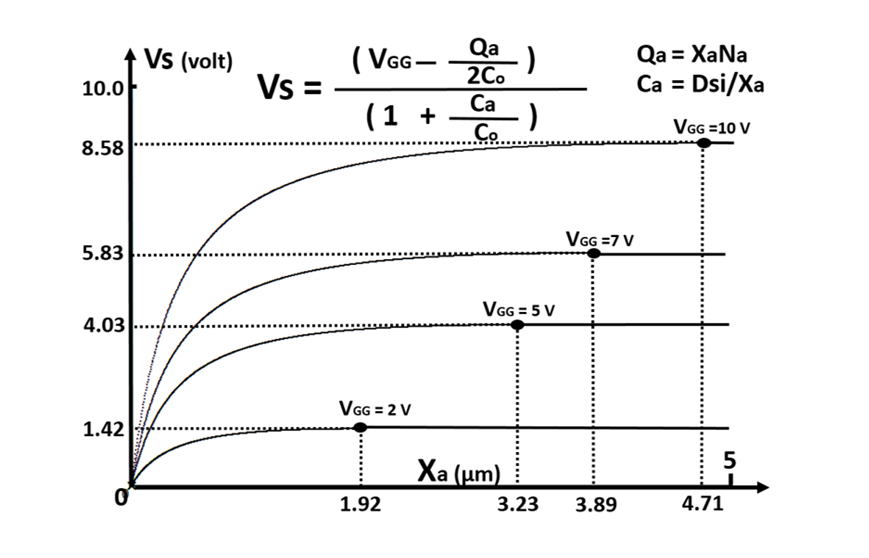

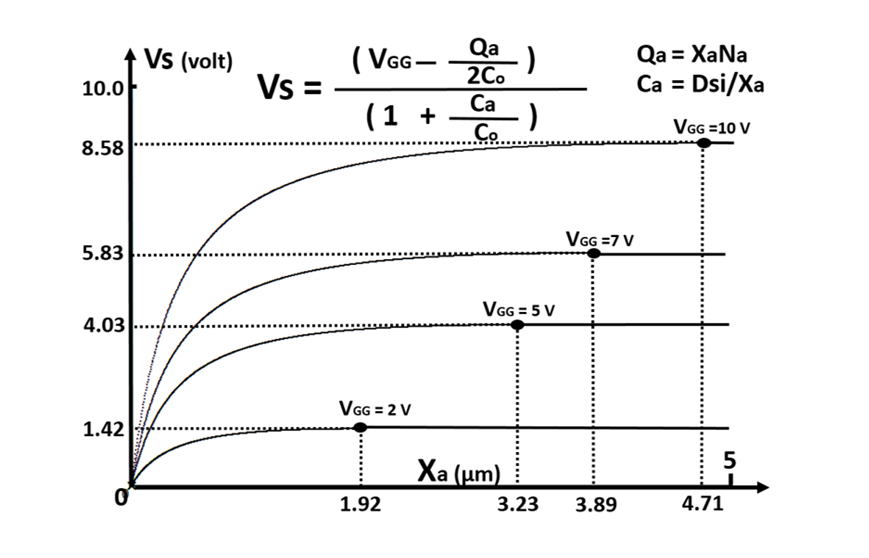

Figure 6

The surface potential plotted against the depth Xa of the buried P+ layer

with the offset gate volatge VGG as the parameter.

If we form properly a heavily doped buried P+ layer as shown in the Fig.

6

we can still have the same turn on thresh hold voltage Vth by choosing properly

the depth Xa of the buried P+ layer. However, we can reduce the depth Xd of

the depletion region as

Xd = { 1 - ( Na / Np ) } Xa + (Co/Np) ( VGG -Vsp ) … (32)

And the surface potential Vs now is given below.

VGG - Vs = WA{ sqrt ( 1 + 2 WGG / WA **2 )- 1 } … (33)

Here we defined the parameters, WA = Vp + b Vq and WGG= 2 VpVGG + b Vq**2

with b = (Np/Na) - 1, Vp = DsiNp/Co**2, and Vq =XpNp/Co.

Here we now have a new value Vs for the surface potential.

Note that if we set Np = Na, we have the same surface potential Vs and

the depletion depth Xd as before in the uniform doping case.

Note that if we set Np =Na, we have b=0 and WGG/WA**2 =VGG/VA.

Then, we return to the uniform doping case.

In the extreme case when the buried P+ layer is very heavily doped,

we have the boundary condition V(x) = Vsub at X=Xp, since the potential

of the buried P+ layer will be fixed or pinned by the substrate voltage Vsub.

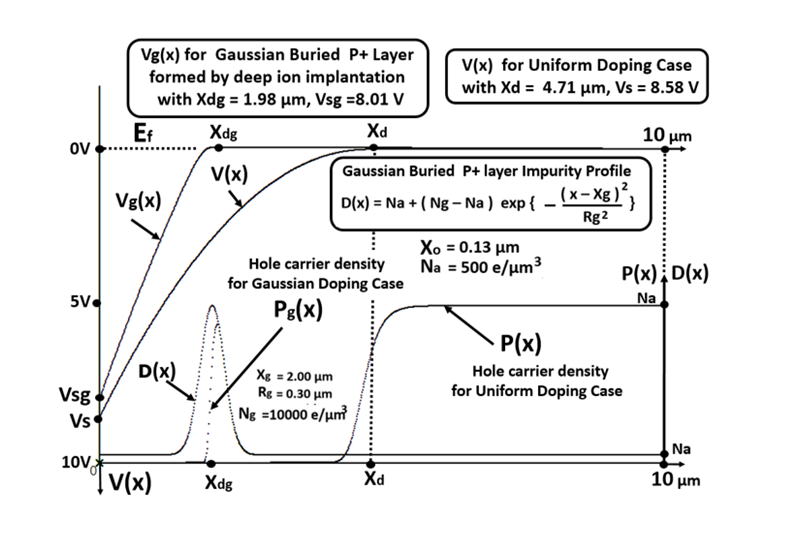

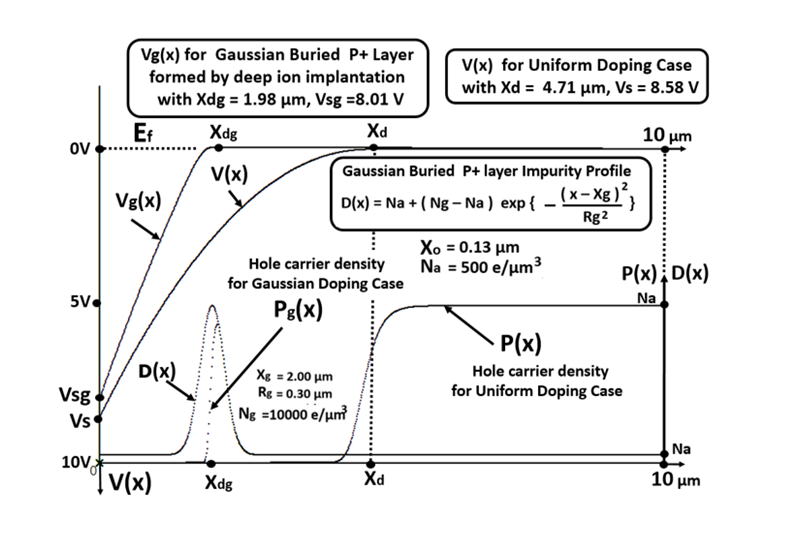

The internal potential profile Vg(x) and the majority carrier hole

density Pg(x) for the case of Gaussian Buried P+ Layer are shown

in comparison with the Uniform Doping Profile case

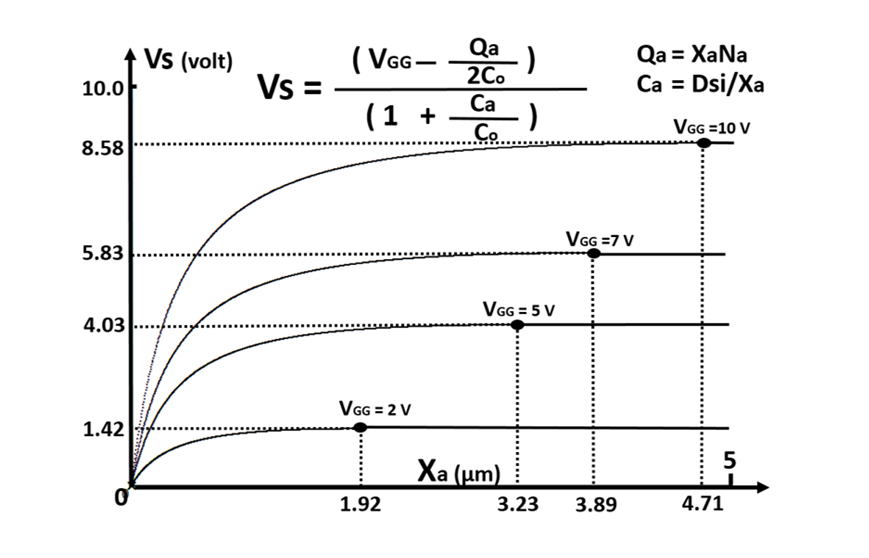

We can obtain the surface potential Vs as a function of the depth Xp of

the buried P+ layer with the offset gate voltage VGG as a parameter

as shown in Fig. 6.

Vs = ( VGG - Qa / 2 Co ) / ( 1 + Ca / Co ) … (34)

Here we defined the parameters Qa = NaXa and Ca=Dsi/Xa.

Figure 6

The surface potential plotted against the depth Xa of the buried P+ layer

with the offset gate volatge VGG as the parameter.

If the value of Xa is larger than the depletion width Xd of the uniform

doping case, we have no change in the value of the surface potential Vs.

However, as we increase the gate voltage at the point where the depletion

depth Xd reaches the depth Xa of the buried P+ layer, the depletion will be

expanded slowly into the highly doped P+ layer region.

The signal electron charge Qsig that we can handle in this MOS capacitor

is proportional to the surface voltage difference created by the gate voltage

swing VGG. As can be inferred from Fig. 6, if we set the depth of the

buried P+ layer to be about Xa = 2μm, we still can handle about the same

amount of the signal charge Qsig that we would obtain for the uniform

doping case. This means we can reduce the depletion depth down to 40 %.

Since we had the bulk dark current 1208 e/μm3 for our case study, this

means in our rough estimation that the depletion depth of Xd=4.71μm

gives the dark current of 5690 e/μm2 while the depletion depth of

Xd=1.92 μm can reduce the dark current down to the value of 2319 e/μm2 .

For this MOS structure to be applied as an efficient MOS capacitor type

light detecting device, the doping level D(x) at the vicinity of the silicon

surface around x = 0 may be adjusted. The impurity doping profile D(x)

can be a Gaussian in particular when the process is defined to have a P

type well formation with the Gaussian hole carrier rich profile peaked

at x = Xp , which prevents the bulk dark current from the deep silicon

substrate reaching the silicon surface charge collection layer at x = 0 .

D(x) = Na + (Np -Na) exp { - ( x- Xp )**2 / Rp**2 } ………(35)

The potential curve V(x) obtained by the depletion approximation is

compared with the numerical calculation at the onset of the strong

inversion. For the Gaussian doping profile D(x) , Fig. 7 shows the

electron potential curve Vq(x) for our case study with the offset gate

voltage VGG of 10 V, the peak impurity doping level of Np = 10000 e /μm3

at the position Xp = 2μm with the spreading tail factor of Rp = 0.3μm.

Figure 7

The internal potential profile Vg(x) and the majority carrier hole

density Pg(x) for the case of Gaussian Buried P+ Layer are shown

in comparison with the Uniform Doping Profile case

At this gate turn on threshold voltage condition N(0) = Po , since both the

depletion approximation and the exact numerical calculation must satisfy

the same boundary conditions at the surface x = 0, we must obtain

the same value for the surface potential Vs = 0.541 V in both calculation

methods.

We impose the same value for the surface potential ( Vs - Ef ) = 0.541 V

but we have slightly different values for VGG and the electric filed Es

at the condition of the strong inversion condition N(0)=Po.

By forming the heavily doped Gaussian P+ buried layer, we can have

a smaller space volume of the bulk space depletion region and the bulk dark

current is lowered because the bulk dark current is proportional to

the depletion space volume. However, we still can keep the surface

doping level D(0) as low as the substrate doping level Na. And we can

perform the strong inversion operation mode almost in the same manner

as in the uniform doping wafer case. This buried P+ layer formed by the

high energy deep ion implantation technique was the savior of the image

sensor production engineers in the early history of image sensor developments.

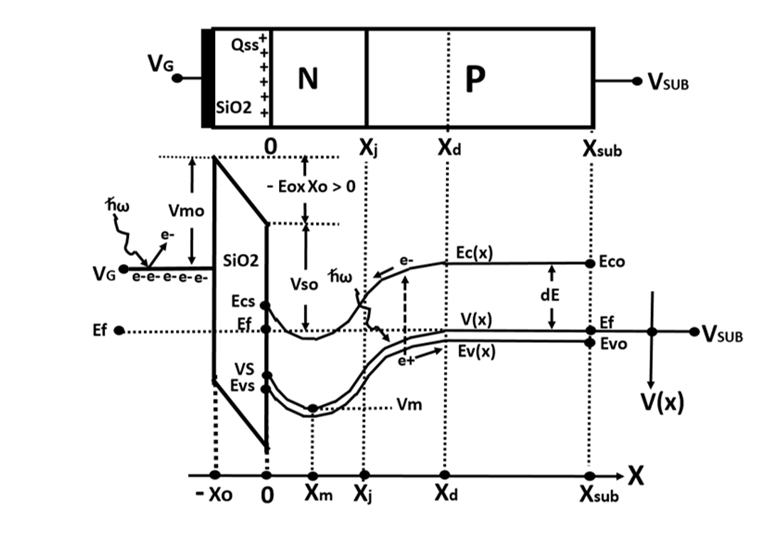

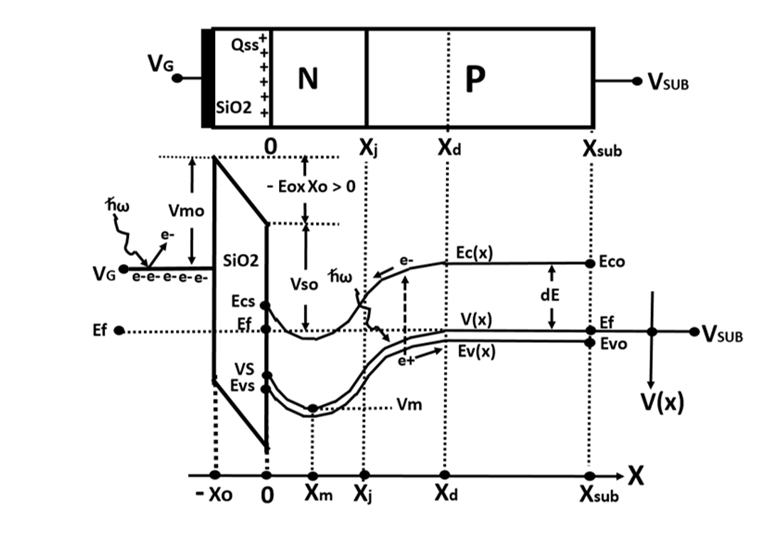

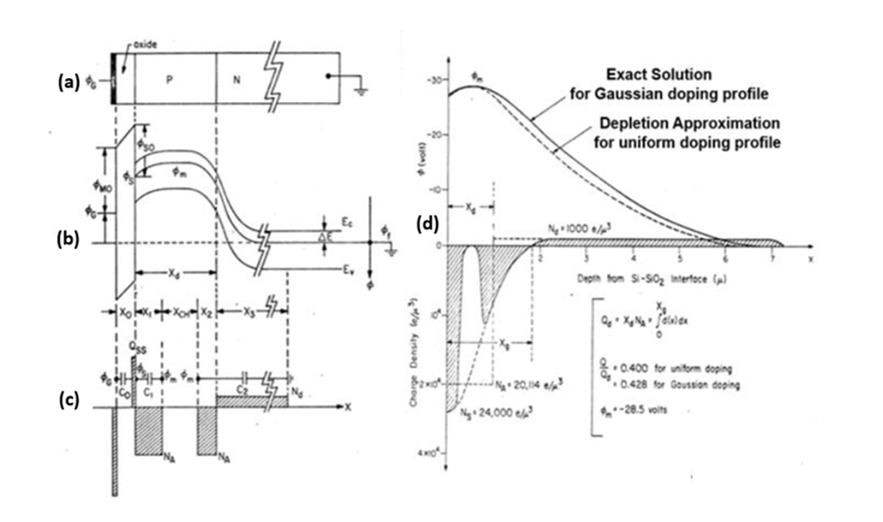

(2) Electrostatic Analysis of Buried Channel MOS Capacitor Structure

2.01 Buried Channel MOS Capacitor Structure with the flat band gate voltage

The one dimensional geometric structure for a buried N type channel charge

couple device is illustrated in Fig. 8 with the flat band gate voltage VG = VFB

at the thermal equilibrium condition.

Figure 8

The NP junction type Buried Channel MOS Capacitor Structure

with the flat band gate voltage

The structure consists of a metallic polysilicon gate

followed by a layer of silicon dioxide of thickness Xo

which rests on the bulk silicon wafer with the doping

level of Na with the N type buried channel layer of

the impurity doping level of Nd for mobile electron

charge carriers e- to move around freely near the

surface.

The potential energy V(x) is define as before

with the Fermi level at the P type bulk substrate

as the reference voltage.

Near the silicon surface at the thermal equilibrium,

the electron carrier density is equal to the doping

level Nd of the buried N layer and we have the

following relationship.

Nd = No exp { ( Vs-Ef ) / (kT/e) } ……(36)

Since we also have PoNo = Ni2, and with Po being almost equal to Na, we obtain

the expression for the built-in potential VB of the PN junction.

( Vs - Ef )=VB = ( kT / e ) ln ( Na Nd / Ni2 ) …… (37)

At this value, the band at the surface is flat, and the flat band voltage is given by

VFB = ( kT / e ) ln ( Na Nd / Ni2 ) + Vms …… (38)

2.02 Buried Channel MOS Capacitor at the dynamic operation mode

Fig.9 shows the electrostatic potential V(x) of the buried channel MOS capacitor at

the dynamic operation mode when the buried channel layer is completely depleted

of the majority carrier electrons.

Figure 9

The NP junction type Buried Channel MOS Capacitor Structure

at the dynamic operation mode when the buried channel layer

is completely depleted of the majority carrier electrons.

Since the potential gradient dV(x)/dx > 0 at the silicon

water surface x =0 in this case, we have the following

relationship from the Gauss law,

Qss = -Dsi Es + Dox Eox …… (39)

We also have the relationship

VG = Vs - Vso - XoEox + Vmo …… (40)

We define, similarly as before, the offset voltage VGG as below.

VGG = VG - ( Vmo -Vso ) + Qss / Co …… (41)

Then we obtain the boundary condition at the silicon surface as before.

Vs + Dsi Es / Co = VGG …… (42)

Figure 10

The NP junction type Buried Channel MOS Capacitor Structure

at the dynamic operation mode with the majority carrier mobile

electrons present in the buried channel layer.

In the more general case as described in Fig. 10 we consider the majority

carrier mobile signal electrons Qsig present in the buried channel layer,

which is given as

Qsig = ( X2 -X1 ) Nd, …… (43)

We can express by depletion approximation the minimum potential Vm and

the depletion edges, X1, X2 and Xd in terms of the signal charge Qsig and

the offset gate voltage VGG. The internal potential function V(x) is given as below.

V(x) = Vm - ( X1 - x )2 Nd / 2 Dsi for x in [ 0, X1 ] …… (44c)

V(x) = Vm for x in [X1, X2 ] …… (44b)

V(x) = Vm - ( x - X2 )2 Nd / 2 Dsi for x in [X2, Xj ] …… (44c)

V(x) = Ef + ( Xd - x )2 Nd / 2 Dsi for x in [Xj, Xd] …… (44d)

V(x) = Ef for Xd < x …… (44e)

Since we have V(x) = Vs at the silicon surface x = 0 and the internal

potential V(x) and its gradient dV(x)/dx are continuous inside the silicon

wafer, we have the following relationships.

Vs = Vm - Nd X12 / 2 Dsi …… (45)

Es = Nd X1 / Dsi …… (46)

Vm - ( Xj - X2 )2 Nd / 2 Dsi = Ef + ( Xd - Xj )2 Nd / 2 Dsi …… (47)

( Xj - X2 ) Na = ( Xd - Xj ) Nd …… (48)

Although the computation is very cumbersome, we can calculate,

the values of the six unknown physical parameters, Vm, Vs , Es, X1, X2

and Xd in terms of the offset gate voltage VGG and the signal charge Qsig.

We first introduce the following seven parameters, a.b.c d, A,B and C.

a = ( Nd + Na ) / Na …… (49a)

b = ( Dsi / Dox ) ( Na / Nd ) …… (49b)

c = { Xj - ( Qsi / Nd ) } / Xo …… (49c)

d = ( VGG - Ef ) / VA …… (49d)

A = a*c - b …… (50a)

B = a*c*c -2* d * b*b …… (50b)

C = A - sqrt ( A2 - B ) …… (50c)

Then we can calculate the value of the surface electric field Es from the relationship

Es = C Nd Xo/Dsi …… (51)

Then subsequently we can calculate X1 from Eq. (46), X2. from Eq. (43), Xd from Eq. (48),

Vm from Eq. (47) and finally Vs from Eq. (45) above.

Ref(1)

“Barrier Energies in Metal/Silicon Dioxide/Silicon Structure,”

by B.E. Deal, E. H. Snow, and C. A. Mead in the Journal of Phys.

Chem. Solids, 27, p.1873 (1966).

Here we denote the metal oxide work function by Vmo, which has 3.2 eV

for the aluminum metal and the oxide semiconductor barrier height by Vso,

which has 4.35 eV for the P type silicon with the impurity doping level

of Na =10000 e/μm3. Then the value of the metal/Sio2/silicon barrier

energy offset value becomes ( Vso ? Vmo ) = (4.35 eV ? 3.2 eV) = 1.15 eV

as reported by Prof. C.A. Mead and his colleges at Caltech in 1966.

At that time, Hagiwara was still a high school student at Riverside Polytechnic

High School in Riverside, California. Riverside city is only one hour drive away

from Caltech in Pasadena, California. Hagiwara moved to Pasadena to study

at Caltech in 1967 till he obtained the PhD degree from Caltech in 1975.

Hagiwara joined Sony on February 20, 1975.

Prof. C.A. Mead and Prof. T. C. McGill were PhD thesis advisors when

Hagiwara was working for his PhD degree at Caltech from 1972 to 1975.

In 1973, under the guidance of Prof. C.A. Mead and with the graduate

students at Caltech, Hagiwara designed the 128 Bit Multi Comparator

digital circuit chip (2) which was later fabricated in the Intel PMOS process line.

The chip was operated with the clock voltage swing of - 5 V to + 5 V with

the grounded substrate. Later in 1978, Hagiwara published the 380H x 490 V

frame transfer CCD image sensor (3) with the P+NP junction type Pinned

Photodiode with the Pinned SiO2 photo window and the Pinned surface

potential. The chip was operated with the clock voltage swing of + 5 V to ? 5 V

with the grounded substrate. The image sensor was fabricated in the Sony

NMOS process, which is very similar to the original Intel P channel MOS process

that Hagiwara studied at Caltech when he was working as a PhD student

under the guidance of Prof. C. A. Mead and Prof. T.C. McGill.

Ref(2)

C. A. Mead, R. D. Pashley, L. D. Britton, Y. T .Daimon (Hagiwara) and

S. F. Sando, JR, "128-Bit Multi comparator", IEEE Journal of Solid State

Circuits, VOL.SC11, No.4, October 1976. The silicon chip was fabricated

in the Intel PMOS process line with the clock voltage swing of ? 5 volt

to + 5 volt with the grounded substrate.

Ref(3)

Yoshiaki Daimon Hagiwara, Motoaki Abe, and Chikao Okada,

“A 380H x 488V CCD imager with narrow channel transfer gates,”

Proceedings of the 10th Conference on Solid State Devices, Tokyo, 1978;

Japanese Journal of Applied Physics , vol. 18, supplement 18-1,

pp. 335-340, 1979.

The FT CCD image sensor with P+NP junction type

Pinned Photodiode was fabricated in the Sony NMOS process with

the clock voltage swing of + 5 volt to - 5 volt with the grounded substrate

with the oxide thickness of Xo = 0.13μm and the substrate wafer

doping level of Na = 500 e/μm3 .

Ref(4)

The value of the surface potential at x = 0 at the strong inversion

condition is given as

V[0] = Vs = Ef + 2VB = Ef + 0.541 V . … (A-1)

But we do not know the value of the offset gate voltage VGG.

We have to find the right value of the offset gate voltage VGG

to give the right surface electric field Es and the other boundary

condition at the bulk V(sub) = Ef. In our numerical analysis, we

divide the range [ 0, Xsub ] into N subrange and set dx = Xsub/N.

We then choose first a possible candidate value for VGGG in the

range [VGG1, VGG2] centered at the value of the offset gate

voltage VGG obtained by the depletion approximation. And then

with the values of VGG and Vs=V[0], we calculate Es from the

boundary condition given by Eq. (5). Then the value of V[1] can

be obtained from the relationship

( V[0] - V[1] ) / dx = Es. … (A- 2)

Then we can calculate the value of V[2] by rewriting the Poisson

equation Eq. (1). First, the value of the right side term of Eq. (1)

can be calculated by using the value of V[i] for i =1. . We then

write the second derivative of the internal potential function V(x), as

d2V(x)/dx2 =( V[i+1] -2V[i] + V[i-1] )/dx2 … (A-3)

Then we can get the value of V[i+1] once we know the values

of V[i] and V[i-1]. By iterations we will get the value of V[N]

at the silicon bulk edge at x = Xsub. If the original value of

the offset gate voltage VGG was not correctly chosen then

we would not have the right value for V[N]. But by computing

numerically many values of V[N] by scanning the offset gate

voltage VGG in some possible realistic range [VGG1, VGG2] ,

we eventually can get the right value of the offset gate voltage

VGG for V[N] = Ef.

**************** Under Construction *******************

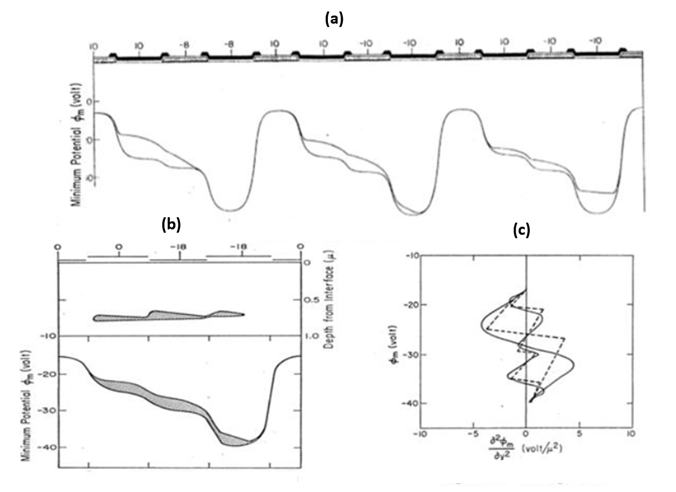

Figure 11

The electrostatic potential and the charge distribution in

Buried Channel CCD with the Gaussian doping profile

compared with the depletion approximation.

Figure 12

The electrostatic potential and the charge distribution

in Buried Channel CCD obtained by time domain (t) and

two dimensional ( x, y ) numerical computation solving

simultaneously the Poisson Equation in the ( x, y ) domain

and the continuity equation in the ( t, x ) domain.

Figure 13

NP junction type photodiode at the thermal equilibrium with

a heavily doped region in each side forming an Ohmic contact,

pinned by the external aluminum metal terminal voltage. The

charge carriers can pass thru the Schottky barrier by tunneling

Figure 14

Schottky Barrier NP junction type photodiode with a transparent

metal electrode with the partially filled N type buried channel

charge collection and storage region.

Figure 15

Schottky Barrier NP junction type photodiode with a transparent

metal electrode with the completely empty N type buried channel

charge collection and storage region by complete charge transfer

operation mode to the adjacent charge transfer device (CTD).

The dashed line shows the potential of the charge collection

region at the full capacity and the Shotkky barrier is forward

biased and the excess overflowing signal charge can be drained

to the gate terminal. Hence this Shottky barrier PN junction

photodiode has a built-in vertical overflow drain (VOD) function.

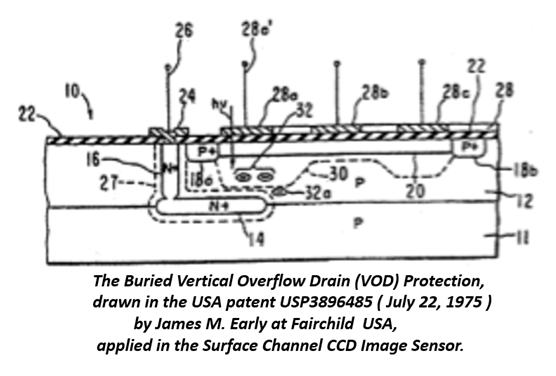

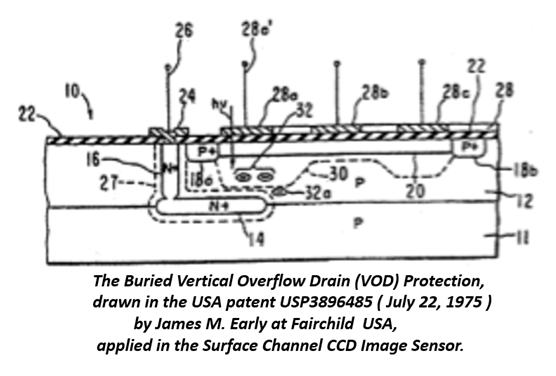

Figure 16

Schottky Barrier NP junction type Photodiode with the

built-in vertical overflow drain (VOD) function, drawn

by Hagiwara at Sony, in Japanese Patent 1975-134985,

(Nov 10, 1975 ) which was used in Interline Transfer

Buried Channel CCD image sensor.

Figure 17

The Buried Vertical Overflow Drain (VOD) protection,

drawn in the USA patent USP3896485 ( July 22, 1975 )

by James M. Early at Fairchild, USA, applied in the

Surface Channel CCD Image Sensor.

Figure 18

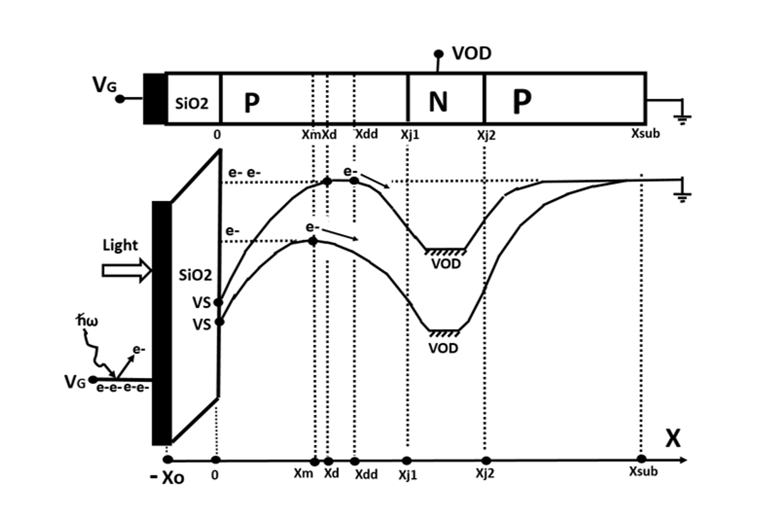

The electrostatic potential of the MOS capacitance type

photodiode with the Buried Vertical Overflow Drain (VOD)

protection , in the USA patent USP3896485, invented

( July 22, 1975 ) by James M. Early at Fairchild, USA,

applied in the Surface Channel CCD Image Sensor.

Return to AIPS HOMEPAGE TOP

return to the AIPS HOME PAGE TOP